Open Standards

In the last decade, the use of open standards has become a requirement for the adoption of new technologies by the automation industry.

“Open Standards” are standards made available to the public and are developed (or approved) and maintained via a collaborative and consensus-driven process.

This process usually is managed by the corresponding Standards Development Organizations or SDO, which generally are non-profit entities whose purpose is to maintain and improve the standard through its lifecycle.

“Open Standards” are meant to facilitate the interoperability and data exchange among different products or services and are intended for widespread adoption.

The term “open standards” used to be linked with software development, but today it implies the concept of hybrid interconnected platforms that include both software and hardware.

Background history

This concept was a consequence of a discovery made by companies and end users: the adoption of a unified environment was more efficient than repetitive and/or incompatible software asset developments. The most notable proof of success of this approach is the Internet.

It may be difficult to understand how disruptive the open standards concept was in the 70s. The idea looks counterintuitive initially because it implies sharing R&D data with your competitors.

But when you reach levels of economy of scale, in any specific market there are limits to the market share that a single specific, proprietary, and closed technology can reach.

Open Protocols, Integration Standards, Technology, and an example

The Open Standards approach started to appeal industrial automation suppliers and users in the late 80s.

We can get a better understanding of the process of adoption of this approach by reviewing a particular example:

One successful example of implementation of open standards can be seen in the combined use of HART, OPC and FDT/DTM technologies. These technologies differ vastly between each other, but thanks to the use of open standards they can work seamlessly together.

HART

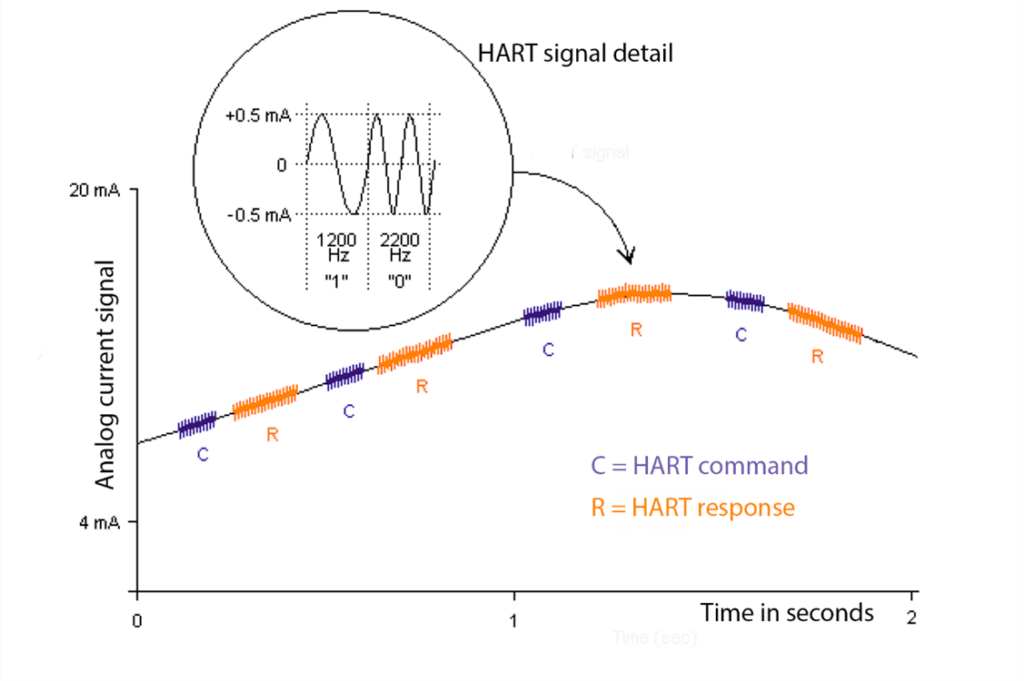

The HART protocol was a Fisher Rosemount’s development employed in the first generation of Smart field devices, based on the use of Bell’s Frequency Shift Key (FSK) encoding technology.

The FSK encoding method employed in HART.

Afterwards, every competitor presented its own smart field devices using FSK technology variants. Traditionally, the outcome of such a situation was a fierce competition among suppliers that created a fragmented market without interoperability support.

The innovative path adopted by Fisher Rosemount avoided this outcome. The company chose to release HART technology to the public by means of an SDO called the HART Foundation, a non-profit entity that would be responsible for the maintenance, diffusion, and development of HART Technology. Any manufacturer interested in HART smart field devices could become a member of the Foundation and get access to the specifications and the certification process for its devices through the compliance tests of the HART Foundation.

Today, HART is the most used communications protocol for smart field devices in process applications worldwide.

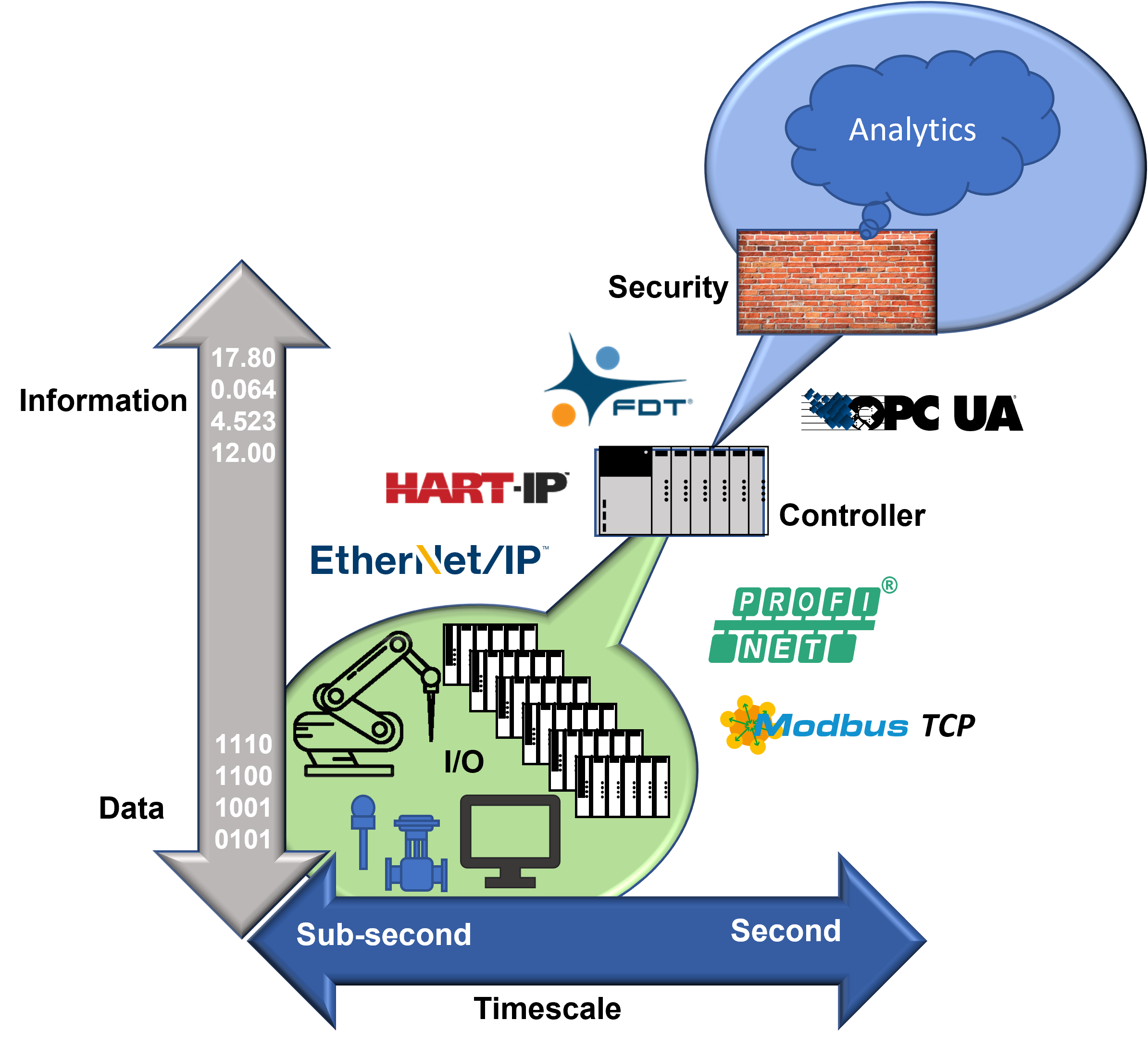

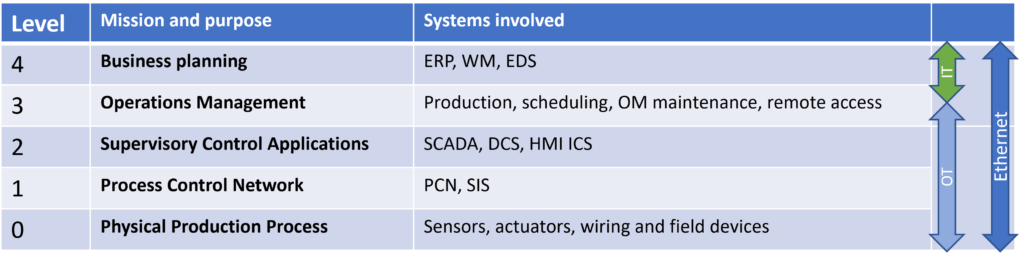

IT/OT integration in Industrial Networking

In the last 10 years, the digitalization of industrial processes has received a significant push to converge the two kinds of networks used in automation applications: IT (Information Technology) and OT (Operation Technology) networks.

Theoretical model of IT/OT integration, according the ISA95 standard

IT technology used open standards from its early origins including the use of Ethernet networks, while OT technology origins were based on proprietary serial RS-485 networks.

Early attempts to link both kinds of networks used interfaces (a.k.a. gateways) that linked their physical layers and performed protocol translations.

Protocol translations limit the transparent exchange of data and physical layer characteristics created data transfer speed rate limits which caused bottlenecks.

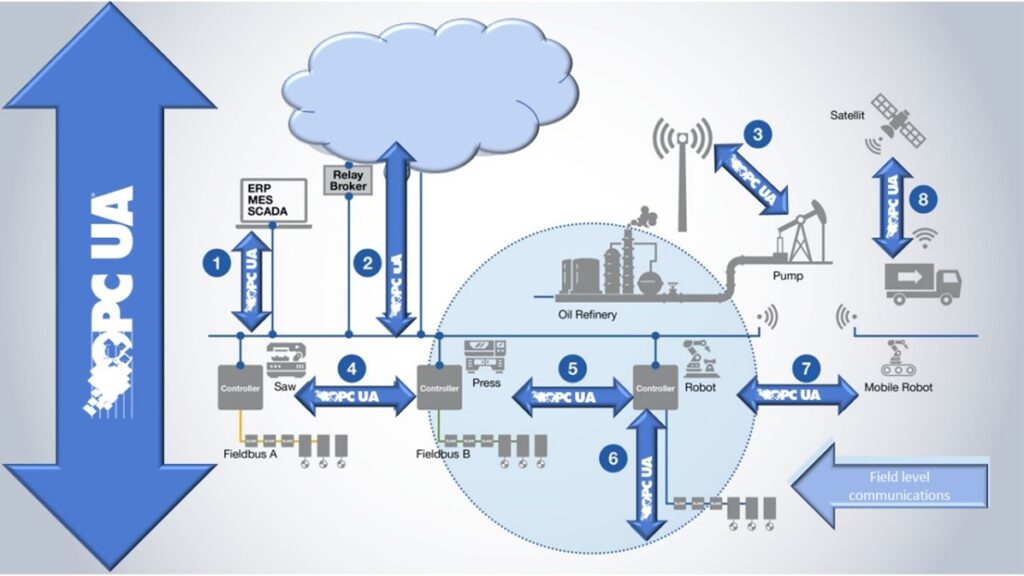

OPC UA

The software layer that enables IT/OT integration is the OPC UA standard. OPC has a long and complex evolution story. Starting as a Microsoft specific technology called OLE (Object Linking and Embedding), created as an enhanced replacement to DDE (Dynamic Data Exchange), the first attempt allowed data to be exchanged between applications in a Windows environment.

OLE allowed the operating systems (OS) different types of automatic data exchange between applications and used object-oriented programming, a great improvement back then.

OLE used a technology called COM (Common Object Model) to allow the creation of reusable code objects. It was superseded by DCOM technology, which added networking support functionality.

The use of DCOM across Windows based automation platforms created several problems: it required a common DCOM version installed in all the network nodes, but software patching and upgrading made this difficult. DCOM has been, largely, replaced by .NET technology which uses the Windows Communication Foundation platform compatible with Web based services.

An automation taskforce developed a version of OLE optimized for process control applications, known as OLE for Process Control. Later it was renamed as OPC (Open Platform Communications) to signal that the technology had evolved away from its IT origins. OPC was created to allow real time data exchange in plant level applications across various control systems from different suppliers.

The OPC Foundation made OPC independent of DCOM technology, by creating a platform-agnostic version of OPC called OPC UA (Unified Architecture), a middleware solution that allows data exchange in real time across different control systems with independence of the OS being used.

OPC UA offers advantages over OPC and has become the default software backbone for networked industrial automation applications.

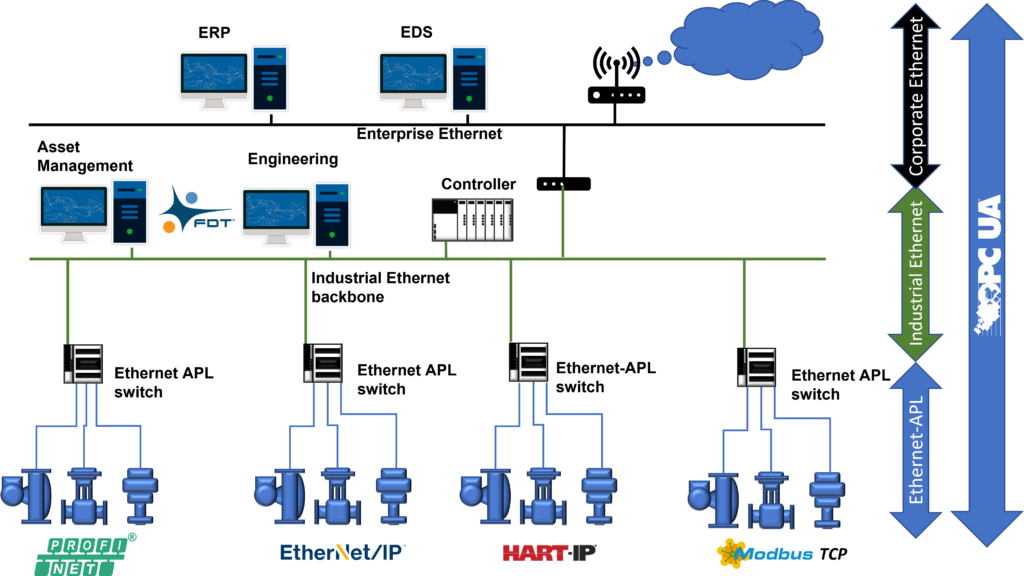

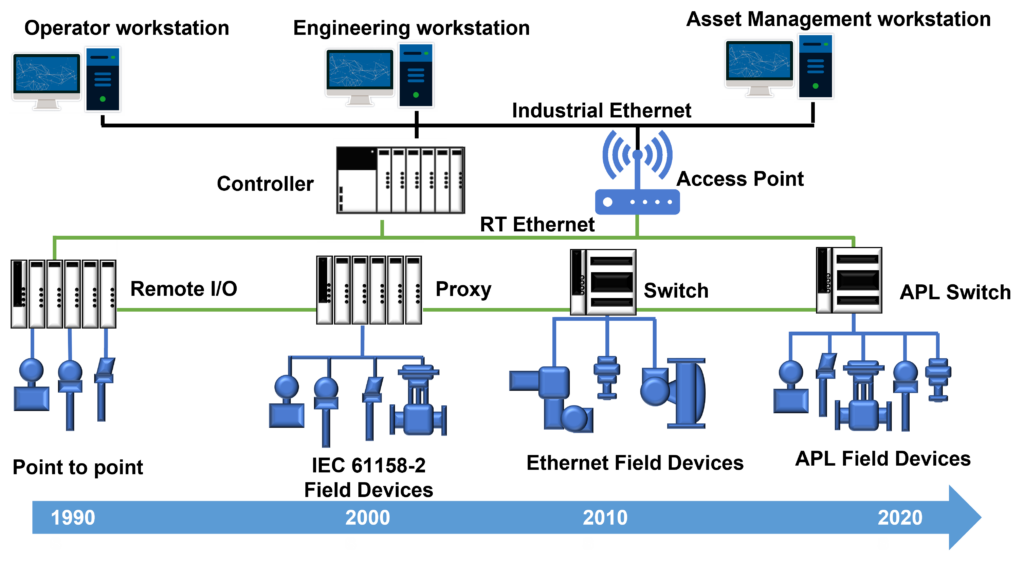

Industrial Ethernet and Ethernet-APL

The hardware side of IT/OT integration used Ethernet technology. Initially deemed inadequate for industrial applications, later developments made possible the use of Industrial Ethernet in industrial environments.

In fact, for many years, Ethernet was also not adequate for field use. With the experience gained in the fieldbus era, Ethernet-APL (Advanced Physical Layer) was developed and the workgroup rescued the best elements of fieldbus, such as explosion protection concepts and the robust Type A cable.

The road to Ethernet to the field

Unlike IEC 61158 fieldbuses, Ethernet-APL is not a communication protocol, it is a new physical layer for Ethernet connectivity to the field. Therefore, end users can keep their existing Industrial Ethernet implementations.

A consequence of digitalization is that every device connected to the network becomes a node that can exchange data bidirectionally with the upper hierarchy levels. Since every node can exchange large amounts of data through a single connection, there is no physical difference in the connection of a single variable device and a multivariable one.

If every device becomes multivariable in an Ethernet network, then the need of a software-based method for its system integration appears.

FDT/DTM

Initially smart devices employed text-based device description files for this task. Newer, more complex devices require a more advanced device descriptor. A software-based approach works better, allowing easy integration of the full set of features and functions of the smart device.

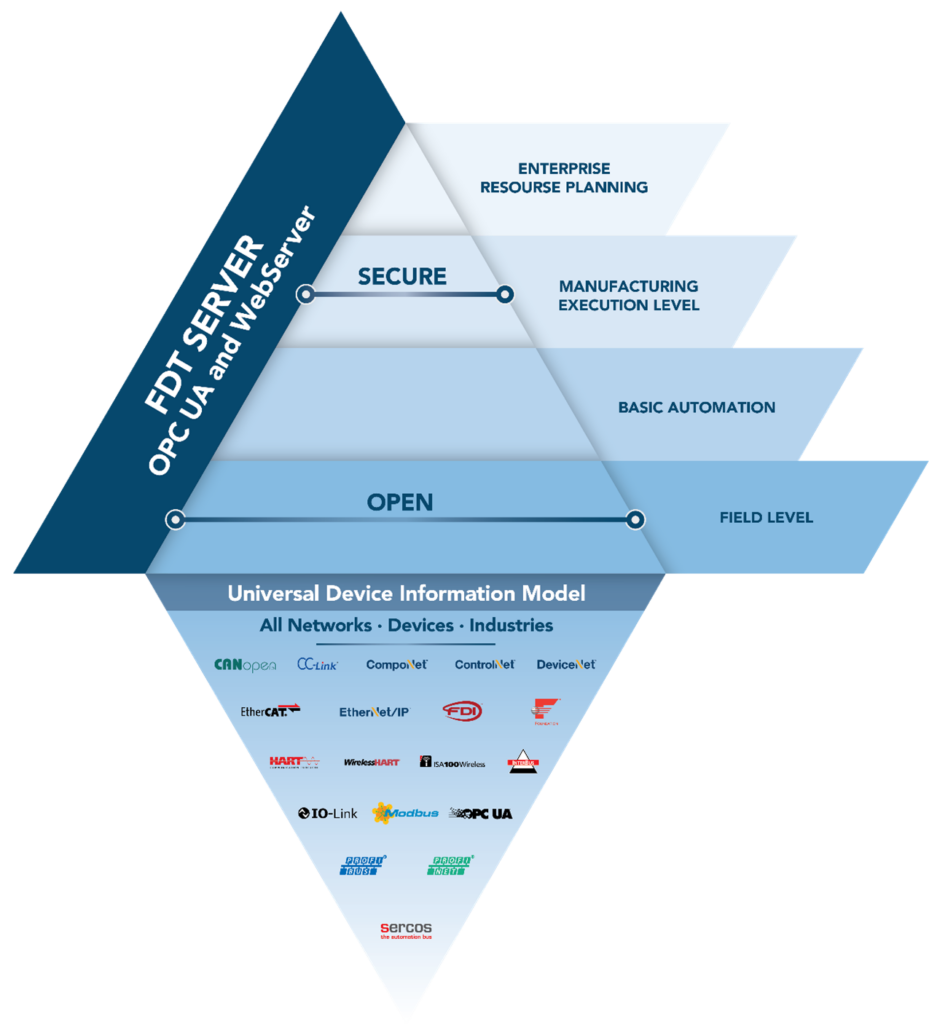

FDT/DTM (technology (IEC 62453), is an intelligent device and lifecycle management standard that provides a single interface to all connected assets in a multi-vendor, multi-protocol environment. The solution is a key enabler for asset management and data-driven operations.

Presented in 2001, when FDT Version 1.2 was made available, the FDT/DTM concept’s objective was to provide end users of smart devices with a single, user-friendly configuration tool compatible with Windows PCs.

In FDT, device descriptors are software-based components, known as DTMs, which run within an FDT-enabled engineering application allowing the connection of smart devices in a unified environment.

FDT/DTM works like an abstraction layer hiding protocol conversion procedures, which are performed by communication DTMs for gateways employed to connect smart devices to FDT-enabled host applications.

A worldwide standard harmonizing system integration

FDT has been widely adopted as the key integration standard streamlining intelligent device management for users today. Tens of millions of DTMs are deployed and serviced by FDT-enabled hosting applications every day all around the globe. The solution is pivotal for increased plant performance for sustained lower operating costs.

The hosting application allows end users to configure devices utilizing a single interface, compared to other technologies that use proprietary software tools to operate and configure devices. This reduces the need for capital and training investment in additional hardware and software.

For example, a current install base of smart instrumentation can benefit from FDT technology by using the Desktop application to configure all the devices on the network from the cozy chair in the control room or any other remote location. Once complete, the user will have central diagnostics, predictive maintenance, and process optimization for all devices in the facility, allowing the user to access devices in real time over the life cycle (engineering, installation, commissioning, production, and maintenance) of the plant.

An evolving modular design fit for every need.

FDT technology has a flexible modular design, so the technology can be implemented as a stand-alone application, integrated into the control system or the asset management software solutions of any supplier.

FDT/DTM technology makes it possible to perform the remote asset management of any smart field device, independent of the communication protocols and vendor equipment used.

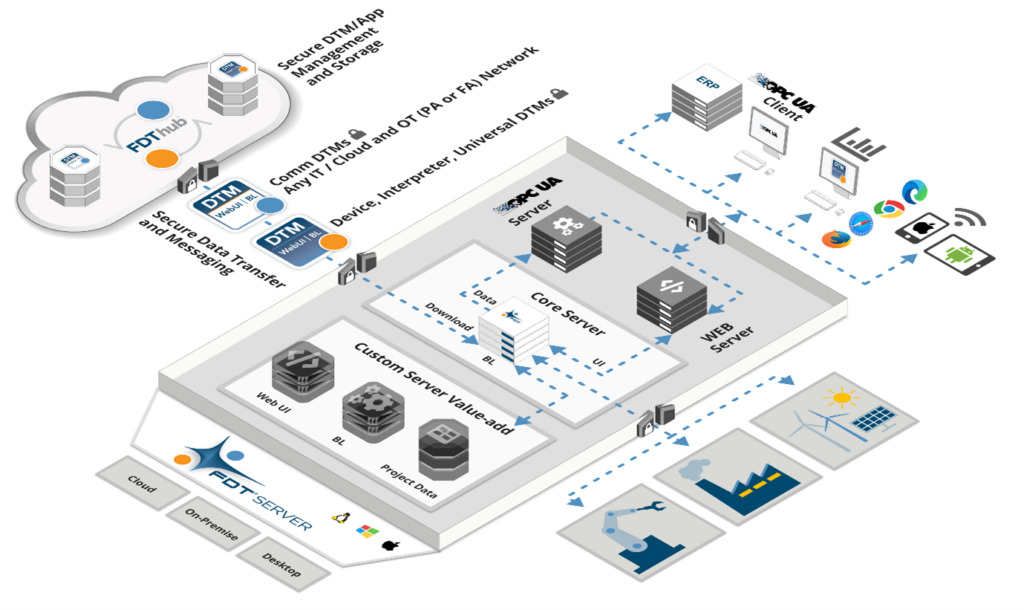

In 2012, FDT version 2.0 was made available, adding client/server functionality for networked environments and OPC UA support to its Desktop engineering application.

In 2020, FDT version 3.0, also known as the FDT Unified Environment (FDT UE) was released offering extensions inclusive of an agnostic operating platform (macOS, Linux, Microsoft), IT/OT data interoperability with OPC UA and Web Services mobilizing field device management. It can work with cloud-based applications and incorporates cybersecurity, mobility, and allows for data interoperability and access across the enterprise using new web-based DTMs.

FDT UE hosting applications include a stand-alone desktop application and the new Server application (also an OPC UA and web server) that offer the embeddable, modular, network oriented, web-based environment delivering services and client-based device management and data-driven operations throughout the architecture hierarchy.

Scalability and future proof

As field devices become smarter, featuring more complex parameterization, and become pervasive in plants, device setup and commissioning become difficult work for human operation. Newer plant requirements like predictive/proactive maintenance, real time diagnostics, and maintenance + optimization systems, in accordance with the NAMUR NOA specification (NAMUR Open Architecture) further increase that workload.

New generations of automation control systems based on Open Standards (OPAF and OPAS) are being designed with the idea of automating the commissioning process via software solutions, a procedure known as orchestration.

The growing importance of information models

During orchestration, the control system must be able to correctly identify, configure and commission any device connected to the network, without being affected by problems such as ambiguous device naming. The solution for this requirement is the use of a standardized device information model, with a hierarchical structure and with the incorporation of semantics support to establish the correct association between device features and protocol parameters, thus enabling the ability to “map” protocol specific parameters to globally standardized terms for these parameters.

PA-DIM (Process Automation-Device Information Model) technology is the most likely device information model to be employed for this purpose. Since both PA-DIM and FDT UE are based on OPC UA, the implementation of this device information model-based commissioning is simplified.

How do these three stories blend into one?

In 2007, the HART Foundation presented HART-IP, a new implementation of the HART protocol ported over Ethernet, fundamentally eliminating the main critique to the technology, its data transfer rate.

In 2022, The Ethernet-APL team (formed by the ODVA, OPC Foundation, PI Organization, and the FieldComm Group) presented Ethernet-APL, a new advanced physical layer for Ethernet that enabled it to reach the field. Ethernet-APL can be used for HART-IP devices.

In 2020, the FDT Group announced the availability of the FDT (3.0) UE (Unified Environment), making FDT the harmonizing standard open to all vendors, networks, devices, information models and industries for intelligent device configuration, management, and data exchange across the enterprise.

Conclusions

By analyzing this integration example, we have seen how three different technologies, one hardware based (HART), other software-based applications (OPC UA and FDT UE) and a communications protocol (Industrial Ethernet) can interact together and provide a unified environment for system integration.

An advantage of the open standards approach is that it can work either for Process Automation applications, like the integration example we have just analyzed or for factory automation applications. FDT UE offers the same functionality when it is employed with factory oriented industrial ethernet protocols like Modbus TCP, EtherNet IP or ProfiNet. The workflow using these different protocols is the same but with FDT DTMs corresponding to VFDs, motor starters and discrete sensor networks.

And all this integration is made possible by the common use of open standards as the underlaying foundation.