Developed and managed by FDT Group AISBL, an international, non-profit corporation consisting of leading global companies active in industrial automation and manufacturing, the FDT® standard provides an open, standardized solution for universal device integration and information exchange for effective asset management.

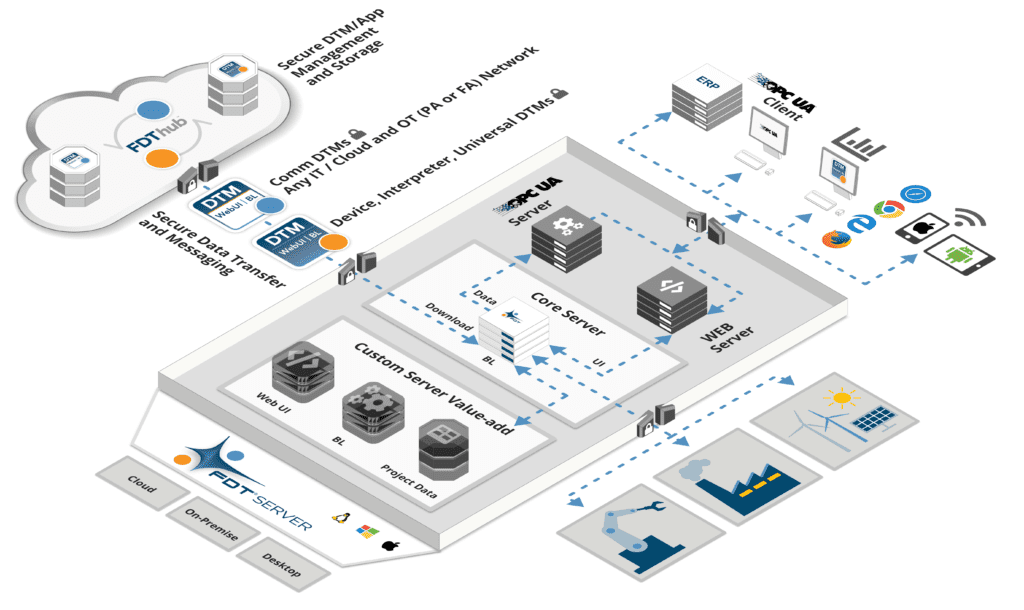

In recent years, major strides have been made to strategically meet marketplace demands to modernize the FDT standard for the digital world while also simplifying the FDT development environment. The emerging FDT IIoT Server (FITS™) architecture (FDT 3.0) is designed for demanding process and factory automation, hybrid automation and motion-related applications. This solution incorporates single-user desktop to multi-user distributed server architectures irrespective of system, device, platform or protocol limitations.

The emerging FITS standard will provide control system and device vendors with the opportunity to advance their intelligent automation solution offerings with standards-based, platform-independent, information-driven business models meeting the requirements of process and discrete manufacturing.

A key advancement with FITS is the ability to create a Graphical User Interface (GUI) in HTML5 and JavaScript—eliminating common coding challenges and freeing automation developers from the Windows environment.

What FITS means to the market

For suppliers of industrial control products and solutions, the implementation of FDT is a forward-looking strategy leveraging the new era of automation. The technology has been enhanced to support applications that open the door for standardized sensor-to-cloud and enterprise-wide integration.

The third generation FDT standard, manifested in FITS, is a disruptive technology for modern industrial operations, and a key enabler of the Fourth Industrial Revolution, with an Industrial Internet of Things (IIoT) server-based solution providing advancements for cloud-based enterprise data access, mobility, apps, and the use of augmented reality.

It is important to note that both development and deployment is entirely platform independent for FITS-based FDT Servers and FDT Device Type Managers™ (FDT/DTMs™). In fact, FDT is the only standard offering a complete integration solution with the flexibility to deploy FITS independent of the user’s operating system with backwards computability to the existing installation in the market.

The FITS solution will empower the intelligent enterprise by transforming manufacturing practices, enabling open, secure, flexible, and platform independent deployment architectures for cloud, edge, on-premise, and desktop environments. Its Client/Server-based architecture enables sensor-to-cloud integration with an embedded OPC Unified Architecture (UA) Server and Web Server, as well as built-in security features—making the FITS solution suitable for highly critical to most basic applications.

FDT Group received industry feedback that inclusion of OPC UA in the FITS solution was important to product suppliers. OPC UA is a well-adopted international interoperability standard for reliable and secure exchange of information. It represents the information and communication layer in the RAMI 4.0 architecture, and is the basis for the Industry 4.0 communication guideline.

Unlike standards that make the use of OPC UA completely optional, with FDT Group’s technology, the OPC UA Server is natively integrated and completely pre-wired within the server developer toolkit so developers don’t have to bother with implementing OPC UA—it’s already part of the tool set.

With FITS, all device DTMs automatically make their data and health information available through the OPC UA Information Model used across all industrial control networks in factory and process automation. This rich dataset is then exposed through the OPC UA Server built into the FDT Server. As such, any OPC UA Client with authenticated access to the Server can acquire real-time data and health information from any connected device.

Why developers should be interested

Automation product developers have many reasons to be interested in the latest FDT technology developments. Release of the FITS architecture, set for the first quarter of 2020, will dramatically change the outlook for the worldwide supplier community. The modernized approach inherent in FITS “lowers the bar” for vendors seeking to take advantage of this innovative technology while greatly optimizing developer performance.

The FITS solution is multi-faceted, scalable and agile, and can be utilized in a host of diverse operating environments due to its platform independent approach employing the .NET Core Framework. The technology’s standardized interfaces and infrastructure will boost connectivity to a new level by offering cloud deployment and mobility services, and thereby make field devices ready for IIoT and Industry 4.0. At the same time, the use HTML5 and JavaScript allows for a modernized graphical interface to support development activities.

FITS will also expand mobile access to detailed device diagnostics across equipment vendors and all FDT-supported network architectures, while eliminating the need for advanced coding or programming in the supervisory control system.

At the same time, OPC UA and mobile remote access will have a significant impact on solutions intended for plant and factory maintenance personnel, who are looking to implement condition-based maintenance to reduce their cost for periodic, scheduled repair and troubleshooting activities.

The FDT IIoT Server platform improves the device supplier business model by allowing for creation of a new generation of FDT/DTMs that will seamlessly integrate with any Server or Desktop hosting environment. This approach holds the key to unlocking universal device integration, bridging the current FDT installed base with next-generation technology, while creating an excellent starting point for new applications.

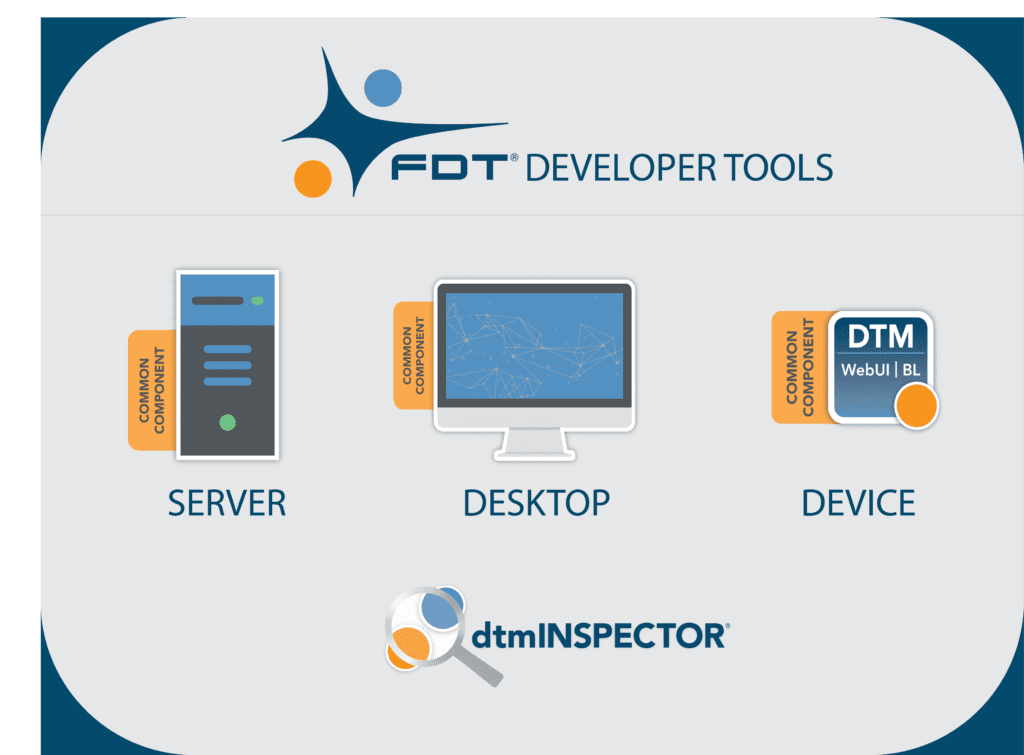

FDT Group is committed to simplifying FITS product development by providing its members with discounts on specifications and other valuable development resources. The goal is to enable automation suppliers to develop FDT Servers, FDT Desktops and DTMs faster and more efficiently than ever before. All base coding to ensure interoperability is done, so vendors can focus on competitive – value-add capabilities, while also bringing advanced product portfolios to market.

Putting FITS-based toolkits to use

FDT Group has a variety of toolkits for Server, Desktop and DTM applications for developers working in the FITS environment. The organization provides versatile Server, Desktop and DTM Common Components to create a library of routines to simplify the development process. It also offers dtmINSPECTOR, which delivers all the properties needed to effectively ensure DTM development compliance for certification by the FDT Group business office.

These platform-independent tools, available for use with any of the major operating systems, ensure specification compliance, greatly enhanced interoperability, and work together to help developers deliver robust FDT-enabled solutions while accelerating time to market.

FDT Group’s second-generation toolkits have been updated based on user feedback to create an environment allowing for quick and easy development. For example, the standard FDT Server Common Components toolkit has a built-in, platform-independent OPC UA Server that is prewired, pretested and ready for immediate deployment. This solution alleviates headaches for developers by eliminating the learning curve for implementing an OPC UA Server and integrating it with an FDT application.

In addition, the FDT Server Common Components toolkit integrates the necessary Web Server to support all the browser-based Clients in the FITS architecture. The toolkit includes a pre-built Web Server so this aspect of the development process is eliminated. In fact, the FDT Server Common Components can even be compiled and employed as a working FDT Server out-of-the-box, without the need for any additional engineering!

For device vendors, the latest FITS (FDT 3.0) standard makes it easier to create compliant device DTMs than ever before. Thanks to the DTM Common Components, DTMs are automatically compatible with OPC UA and compliant with the NAMUR NE 107 status recommendations for predictive maintenance.

Previously, automation suppliers implementing FDT 1.2 spent a considerable amount of time reviewing the standard to find answers to questions and guide their development efforts. With the latest generation standard and tool set, they can take advantage of a completely integrated development environment regardless of the operating system platform.

The FDT 3.0 standard has also been updated with a feature known as “static functions,” which simplifies a wide range of DTM-related activities. Device vendors can now employ a granular runtime environment for processing information for a specific function without running the full DTM.

In the past, developers utilizing the FDT 1.2 standard had to instantiate the entire DTM and deal with large volumes of code in order to obtain current device health or process values. The static functions capability allows them to access smaller segments of code, so it is no longer necessary start-up the entire DTM to obtain the information they need. This solution greatly reduces coding requirements, and at the same time, benefits end-users by minimizing resource requirements and enabling much more responsive system operation.

Lastly, the FITS platform incorporates an “FDThub™” providing a single, centralized location for hosting of all certified, FITS-capable FDT/DTMs. Designed for both cloud-based and on-premise air-gapped system deployment, the repository capability is provided as part of the DTM certification process and eliminates several DTM management headaches for device suppliers. Once a DTM is certified, it is uploaded to the FDThub and made available when the vendor’s product is ready for release.

The FDThub makes it possible to deploy “FDT as a Service” with convenient online access to certified DTMs for distribution to customers. Device discovery triggers automatic download or search results in the case of multiple DTMs.

Utilizing other valuable resources

FDT Group has taken steps to make it easier for developers, end-users, product managers, business strategists, IT/OT professionals and other stakeholders to gather information about next generation universal device integration and asset management enabled by the FITS architecture.

The organization recently held its first European FITS Developer Workshop where more than 60 members and non-members where present to learn about development initiatives supporting the IIoT and Industry 4.0. The event provided an in-depth look at the FITS architecture, while giving attendees hands-on programming experience for FITS-enabled FDT Server and FDT/DTM development using the official Common Component toolkits. Additional developer workshops are planned for the future. For more information, please contact the FDT Group business office [email protected].

In addition, automation equipment suppliers can obtain valuable assistance from recognized FDT Service Providers. These organizations are active members of the FDT Group who stay up-to-date on the latest developments and trends. FDT Service Providers offer training and workshops to teach customers everything they need to know about FDT technology. They can advise about system and device integration, and help suppliers future-proof their system and device management strategy. A full list of FDT Service Providers is available on the FDT Group website.

By becoming an FDT Group member, automation suppliers can access a wealth of information and assistance to make FDT-compliant product development a smooth process. Membership provides an easy entry into the Fourth Industrial Revolution, IIoT and the new era of automation.

Conclusion

FDT Group members, including many of the largest suppliers of industrial automation technology worldwide, will realize opportunities to better serve customers—and improve their business performance—by adopting the FITS architecture.

FITS is a modern, platform-independent solution that migrates the fundamental standard on which FDT is built from the Windows-based .NET Framework to an open .NET Core as well as HTML5 and JavaScript.

The concept of FITS was created to prepare FDT technology for a digital future. It is the key for automation vendors seeking a digital transformation path to keep pace with today’s changing environment and emerging user requirements.

Download Images

FDT Developer ToolsFDThub

FDT IIoT Server Platform