Author: Suriya Selvaraj, VP of Technology – FDT Group

FDT Group, an independent, international, not-for-profit industry association supporting the evolution of FDT® technology, is preparing to launch an Industrial Internet of Things (IIoT) Server-based architecture. This emerging solution is attracting the attention of control system and field device vendors with its universal platform integration approach, which allows for open and secure, yet flexible, scalable, and data-driven service and solutions business models.

This article describes the advantages of the FDT Unified Environment (FDT UE) based on the FDT3 standard for instrumentation suppliers seeking to evolve their product portfolio to keep pace with IIoT and the latest Industry 4.0 initiatives.

FDT Group members, including many of the largest suppliers of industrial automation technology worldwide, see a wide range of opportunities to better serve customers – and improve their business performance – by adopting FDT UE .

DTMs Empower Business Intelligence

Using FDT technology, industrial organizations can parameterize, monitor, diagnose and troubleshoot a wide range of automation devices: from the most simple photo-eye to complex/critical devices. The FDT Device Type Manager™ (FDT/DTM™) is a core component of this solution. It contains the application software that defines all the parameters and capabilities included in a given automation device. The DTM encapsulates all device-specific data, functions, and business rules such as the device structure, its communication capabilities, internal dependencies, and human-machine interface (HMI) structure.

Tens of millions of DTMs are currently deployed around the world. They are a universal tool for lifecycle management of any device/network in the process and factory automation markets. DTMs are designed for smart devices providing data-driven business intelligence. Their data allows for predictive maintenance models for effective asset management.

Traditionally, automation manufacturers have employed two basic types of DTMs: Comm DTMs providing direct access to a communication component for a specific class of device, and Device DTMs that interact with a Comm DTM to access its field device.

Today, FDT DTMs are designed to run in an FDT FRAME (a software application that enables a graphical interface used to configure, maintain and diagnose intelligent devices from different suppliers) such as a lightweight configuration tool, a control system/PLC engineering tool, an operator console or an asset management tool. The FDT-enabled engineering application initiates the DTMs and automatically routes the communications through complex, disparate networks.

FDT Server Environment

FDT Evolves to Empower IIoT Ready Solutions

Industry-driven feedback has been the basis for the growth of FDT technology since the release of the original single-user desktop approach, Version 1.2 specification in May 2001. The latest version of the standard, FDT 2.1, has evolved to a distributed, multi-user, client/server approach. It offers a robust combination of features, including improved security, faster performance, ease of use, and investment protection. These advancements underscore FDT’s transformation as a complete, standardized platform enabling sensor-to-cloud, enterprise-wide connectivity for the new era of automation.

In 2018, FDT Group announced the development of the FDT UE architecture that will provide a flexible platform for deployment of various IIoT-based solutions. FDT UE is multi-faceted, scalable and agile, and can be utilized in a host of diverse operating environments due to its platform independent approach employing the .NET Core framework. This will result in a server architecture that is deployable on a Microsoft-, Linux- or iOS-based operating system and bridges the current FDT install base with support for IIoT applications and other smart manufacturing initiatives.

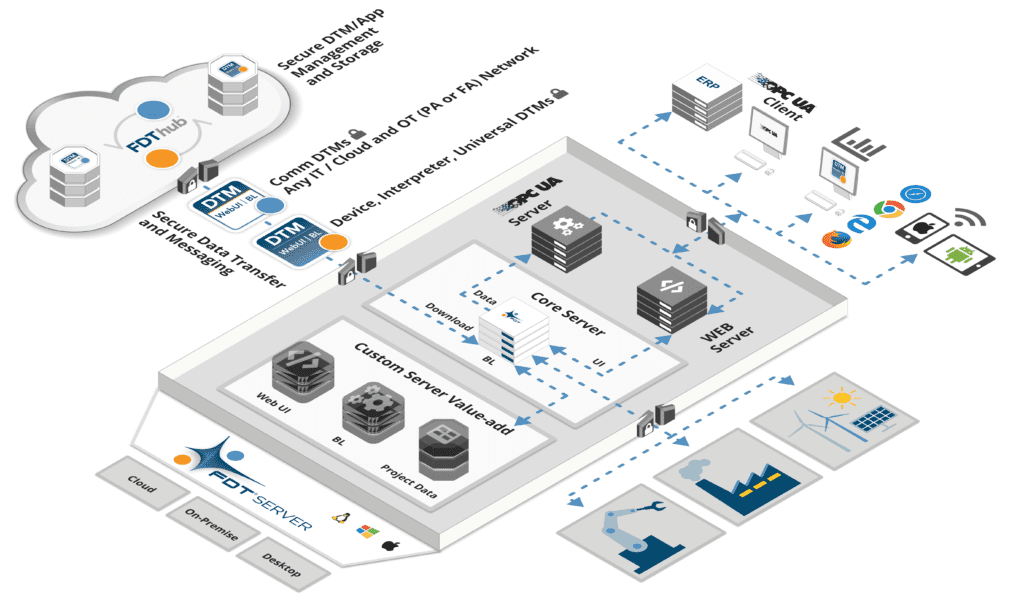

The FDT Server is built around a core server, which serves as a broker for wide range of client/server interactions, whereby communication between key components is standardized for its’ control, OPC Unified Architecture (OPC UA) and web services interfaces. The solution includes an OPC UA Server and a Web Server. The OPC UA Server allows access to DTM data with authenticated OPC UA Clients, whereas the Web Server enables the use of FDT UE DTM web user interfaces on remotely connected, browser-based clients such as smart phones, tablets, and PCs. It also supports the use of apps that improve workforce productivity and plant availability.

The FDT UE solution provides enhanced protection for critical automation data via robust multi-layered security, and leverages vetted industry standards such as Transport Layer Security (TLS) enabling Web Sockets Secure (WSS) and Hyper Text Transfer Protocol Secure (HTTPS).

Intended as a comprehensive, standardized solution for use throughout the industrial automation field, FDT UE will offer greater agility for device integration. It will impact the automation device supplier business model by allowing for creation of a Universal FDT UE Device Type Manager (FDT UE DTM™) that will seamlessly integrate with any FDT UE Server (multi-user) or Desktop (single-user) hosting environment.

FDT UE DTMs hold the key to unlocking universal device integration with important advantages such as platform independence, mobility solutions, and a contemporary development environment to reduce costs and expedite the DTM certification process.

The FDT Server architecture will empower the intelligent enterprise with native integration of OPC UA, as well as comprehensive control and web services for secure mobile, cloud, fog and enterprise-wide applications in the process, hybrid and discrete automation sectors. FDT UE DTM-enabled devices will serve as the hub of data driving robust asset management capabilities. At the same time, integration with OPC UA provides an ongoing infrastructure to make this information available to thousands of other applications and platforms.

New Business Model Solutions

Recent developments within FDT technology, including the emerging FDT UE architecture, promise to deliver a highly refined and rigorously tested solution for companies looking to evolve their smart device portfolios with adaptive and agile offerings.

FDT UE promises to enable an easy and better user experience with greater flexibility, mobility, scalability, and availability with DTMs. Users will be able to take advantage of secure and seamless data exchange/interrogation from sensor to cloud, and achieve new levels of information technology (IT) and operational technology (OT) integration. For device vendors, FDT UE DTMs will provide fit-for-purpose solutions for tasks such deep inspection diagnostics and prognostics enhanced driven by artificial intelligence.

All FDT UE DTMs comply with the NAMUR NE-107 recommendation, which stipulates that operators need a view of the process including the status of the instrumentation in a simple and uniform way – regardless of source device – to support predictive maintenance strategies. The DTMs will be a key enabler for apps intended to view the health of field devices, and subsequently improve maintenance workflows.

The FDT UE Server solution also makes it easier to demonstrate new instrumentation products since a Wi-Fi connection and/or 4G-enabled tablet is all that’s needed to show customers how a FDT3 DTM-enabled device can be configured using a remote server.

A big difference to earlier versions of the FDT standard and FDT UE is separation of the graphical user interface (GUI) and business logic, since the solution is WebUI-based. Furthermore, FDT3 DTMs will work on FDT UE Servers and the FDT UE Desktop (stand-alone) environments.

Device suppliers transitioning from the use of FDT 1.2 technology to FDT3-based DTMs will no longer have to deal with the coding challenges associated with the co-mingled business logic and GUIs in the earlier standard. The move to the .NET Core framework for server and client platform independence with the FDT UE solution does not affect current business logic. Rather, developers utilizing the latest DTMs simply need to install the HTML 5 and Javascript user interface.

By authoring with FDT Group’s Common Component toolkit, developers can automatically ensure their new DTM is OPC UA compatible. This means there is no extra coding needed for OPC UA access, and device data will automatically be accessible across the enterprise for a wide range of process monitoring and data integration purposes.

The deployment of “FDT as a Service” is a natural aspect of the FDT UE architecture, since new devices are supported as part of a comprehensive software-as-a-service model. The availability of a cloud-based repository providing convenient access to FDT3 DTMs for on- and off-premise and standalone applications is an inherent advantage of this solution. The repository allows for convenient DTM storage and device management, not to mention secure data transfer and messaging with proactive user alerts when DTM updates are available. This approach eliminates the headache of distributing DTMs to customers and is part of FDT Group’s streamlined certification process. It provides a secure portal allowing vendors to authorize/de-authorize end-users; view reports and download history; and upload, update, remove, or suspend DTMs as needed.

Paired with Microsoft’s Visual Studio integrated development environment (IDE), FDT UE DTM Common Components assist with the development of platform independent FDT DTMs and help assure compliance with the FDT standard. All the required FDT logic and interfaces are already pre-built and verified so the majority of test cases will automatically pass during the certification process. This solution satisfies basic software coding requirements for automation device manufacturers and frees up their time to focus on unique differentiating features. It also dramatically reduces overall development time for new intelligent devices.

With FDT UE, DTM development efforts can now take place in a more contemporary, platform-independent GUI employing HTML 5.0 and Javascript — greatly reducing the burden of DTM development, and saving time and money when bringing new product offerings to market.

FDT UE DTMs employ responsive touch screen features like soft keyboards, speech-to-text and scanned barcodes as part of HTML 5.0 development, which are mandatory for use with tablets and smart phones. This ensures the familiar interface found on today’s mobile devices is integral to the DTM environment.

The implementation of a modern-based solution and development environment on a day-to-day basis will also help industrial device manufacturers attract and retain a new generation of workers for software programming activities.

In addition, device suppliers can employ FDT Group’s official test and certification tool for FDT UE DTMs, dtmINSPECTOR. Using this tool for prescreening during development helps to ensure specification compliance, greatly enhances interoperability, speeds certification and enables developers to deliver robust FDT-enabled solutions while accelerating time to market.

Conclusion

FDT Group’s ongoing technology and standards development work is aimed at empowering control system and device suppliers with a universal software environment to focus on adaptive business model product solutions that realize the benefits of IIoT for seamless device integration and information exchange across the enterprise.

The emerging FDT UE architecture will enable DTM developers to move from a limited desktop environment to a modern, cloud-based browser environment. They will be able to leverage advantages such as platform independence, mobility and enhanced data security, as well as automatic OPC UA compatibility – with lower cost tools enabling faster development and certification – along with greater DTM accessibility via a central, online repository.

Download Images:

Universal Device Integration with FITS DTMs ImageFDT IIoT Server Platform