Introduction

Yokogawa Electric Corporation provides the OprexTM Vortex Flowmeter VY Series with enhanced self-diagnosis and condition-based maintenance. Compare with other flowmeter types, vortex flowmeters can handle a wider range of fluid types, temperatures, and pressures. Yokogawa developed the world’s first vortex flowmeter in 1969 and introduced the YEWFLO series of general-purpose flowmeters to the market in 1979. It has so far sold more than half a million units around the world.

Digitalization and Inheritance

This new series has been developed with the aim of supporting the implementation of digital transformation (DX) in large plants in the form of efficient and planned condition-based maintenance using FDT technology.

The sensing mechanism are fully compatible with previously released YEWFLO Series products. The vortex shedder bar has a robust and integrated design and is the only device in the industry to feature dual built-in flow sensors and a built-in temperature sensor. The integrated unit can be partially removed and reinstalled, making it easy to maintain or replace when necessary.

OprexTM Vortex Flowmeter VY Series

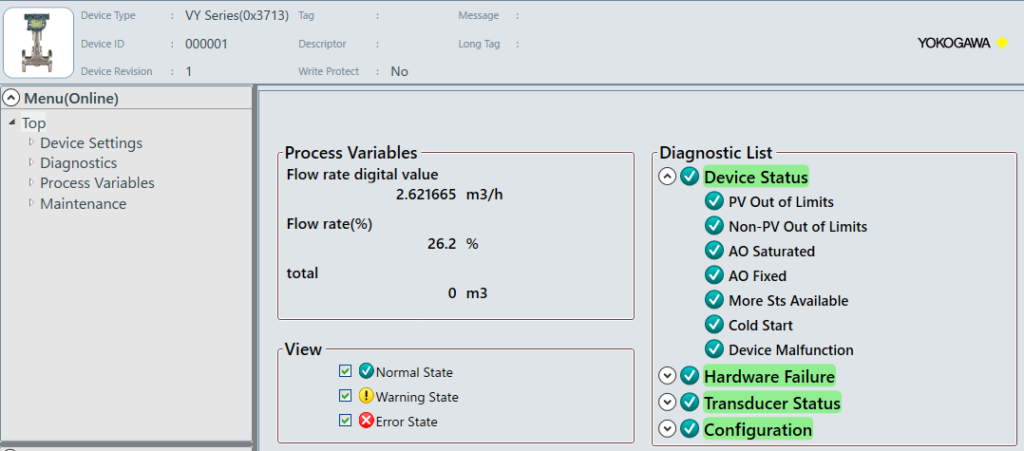

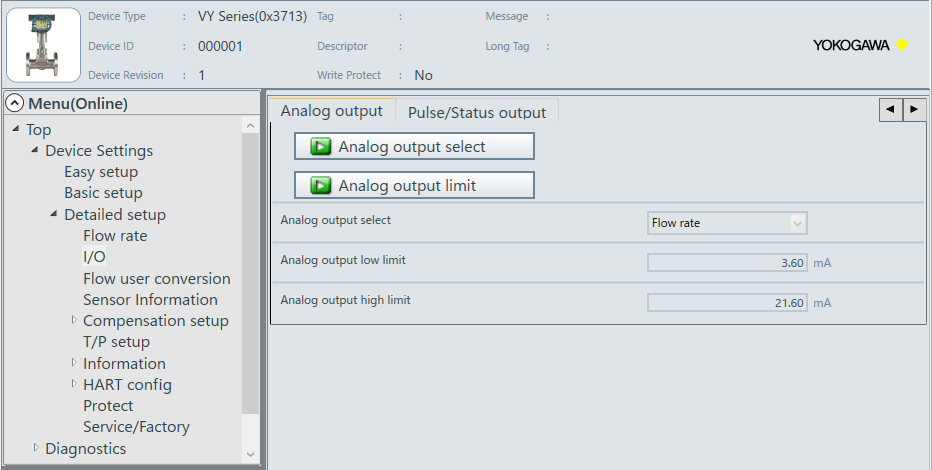

Utilizing readings from a built-in temperature sensor and data from pressure gauges and other external instruments, the Vortex Flowmeters VY Series can perform precise temperature and pressure-compensated calculations and energy calculations, eliminating the need for external calculation devices. On the other hand, to use the instrument effectively, sophisticated settings are required for many parameters, which are generally difficult to handle on handheld terminals with limited information. VY series DTM using FDT technology can be operated on a PC screen, and parameters are arranged and displayed in a menu configuration with related parameters, providing an intuitive user experience, thereby maximizing the instrument’s performance.

Fig.1 Screen of device status for VY Series DTM

Fig.2 Screen of parameter setting for VY Series DTM

FSA130 Verification Tool based on FDT technology provides DX

The digitalization of internal signals is taken further in the VY Series, enabling self-diagnostics to cover all components, including the vortex shedder bar and sensor element. This improves reliability and qualifies these flowmeters for use in safety instrumented loops (compliant with SIL2). With the VY Series, it is also possible to track device integrity parameters and use this data to indicate when sensor capability is expected to deteriorate. Utilizing ‘FSA130 Magnetic Flowmeter / Vortex Flowmeter Verification Tool’ and ‘FieldMate Versatile Device Management Wizard*’, the integrity of VY Series flowmeters can be easily checked from a PC in a remote location such as an instrumentation room, eliminating the need to go on-site to perform maintenance checks.

* PC based configuration tool that performs numerous tasks, including initial setup, daily maintenance, troubleshooting, and configuration backup for device replacement

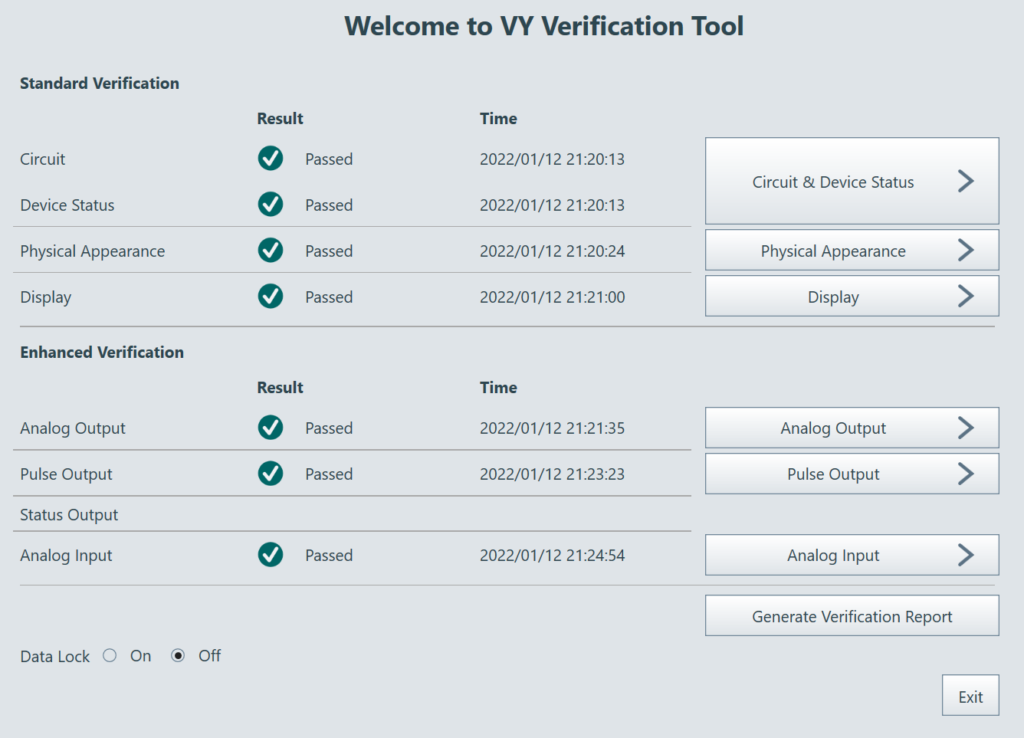

Fig.3 FSA130 verification results screen for all function blocks for VY Series

Fig. 3 shows the results of the device verification execution. The Verification Tool helps users to perform device verification in a wizard format without being aware of complicated parameter settings and displays a summary of the results. The tool also supports report (PDF file format) output, helping to improve the efficiency of daily maintenance operations.

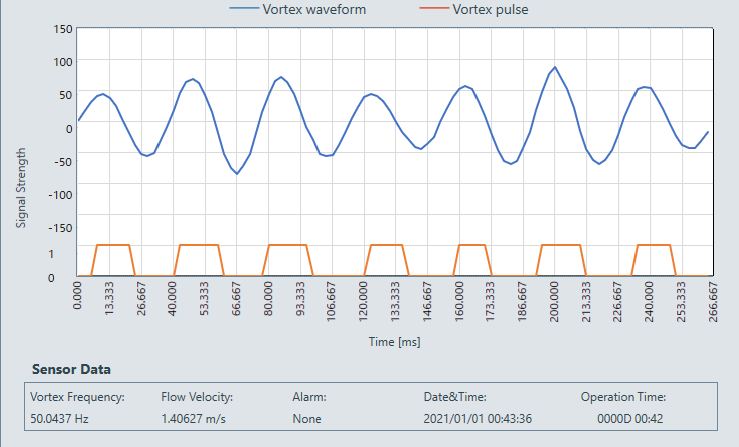

Fig. 4 shows the waveform monitoring screen, a function of the FSA130. It displays the flow sensor signal waveform used to calculate the flow rate of the device (Upper waveform [Blue line]: Vortex signal after device computing, Lower waveform [Red line]: Pulsed signal waveform of vortex signal). The stability of the device output can be visually confirmed.

Fig.4 Screen of waveform monitoring for FSA130

Fig. 5 shows the vortex sensor prediction screen results. During long-term operation of a vortex flowmeter, the characteristics change due to the aging of the sensor element and the effects of fluid deposits on the shedder bar. These changes are accumulated within the instrument and graphically displayed as predicted future values. This function helps the user to know when it is time to maintain the vortex flowmeter or perform other maintenance, thus supporting condition-based maintenance activities.

Fig.5 Screen of Vortex Sensor Prediction for FSA130

System configuration

Figure. 6 shows an example of the system configuration. VY Series FDT2.0 DTM is included in the Device Files that are bundled with the FieldMate software installed on PC. FSA130 Verification Tool runs on the VY Series FDT2.0 DTM. Other external measuring instruments can be used to check/record the health of the VY Series more accurately.

Conclusion

The VY series is based on Yokogawa’s long history of achievement and incorporates the latest digital technologies such as condition monitoring and energy compensation functions, resulting in a highly reliable and easy-to-use product. Furthermore, FDT technology helps the VY series to maximize its capabilities for any customer. Together with these technologies, we will realize and develop the functions required by our customers.

The names of corporations, organizations, products, and logos herein are either registered trademarks or trademarks of Yokogawa Electric Corporation and their respective holders.

FDT Product Case Study Provided by Yokogawa