In all types of industrial plants and factories, there is a need to optimize the management of intelligent field devices such as photo eyes, drives, HMIs, transmitters, meters and valves. For some end-users, management of these devices is difficult and complicated—especially when dealing with multiple suppliers and field communication protocols.

Until now, configuration of intelligent devices was a time-consuming aspect of industrial automation projects. A new, cloud-based repository implemented by FDT Group for FDT Device Type Managers™ (FDT/DTMs™) promises to streamline the DTM installation and update process—saving valuable engineering hours and helping to expedite project execution.

Why FDT/DTMs Are Important

Developed and managed by FDT Group, an independent, international, not-for-profit industry association supporting the advancement of process, factory and hybrid automation, FDT technology enables industrial organizations to parameterize, monitor, diagnose and troubleshoot a wide range of automation devices. The FDT/DTM is a core component of this solution. It contains the application software that defines all the parameters and capabilities for simple to the most complex devices.

Today, millions of FDT/DTMs are installed around the world—from small facilities to large complexes running thousands of Input/Output (I/O) points in demanding industrial applications.

The FDT/DTM encapsulates all device-specific data, functions and business logic rules such as the device structure, its communication capabilities, internal dependencies, and Human-Machine Interface (HMI) structure. It provides a centralized remote access point for horizontal and vertical data flow, allowing for a safer work environment by reducing the number of trips to the field and lowering start-up and commissioning costs.

Experience has shown that FDT/DTMs bridge the chasm between different communication protocols used across facilities and industries and, as such, support a wide range of automation tasks. The traditional boundaries between areas of control do not exist for this technology, making it easier for engineers and production managers to set up seamless asset management.

With thousands of certified Device and Communication DTMs available today, automation, maintenance and operations engineers and managers look for certified DTMs for their current installed base to maximize the full benefit of smart devices.

New Technology Developments

FDT technology is the key to integrating any device, system or network in today’s complex automation architecture. The ongoing advancement of FDT is leveraging major developments like the Industrial Internet of Things (IIoT) and Industry 4.0, so end-users can realize the potential of decentralization, interoperability, integration, as well as a unified view of all data and functions across disparate control applications.

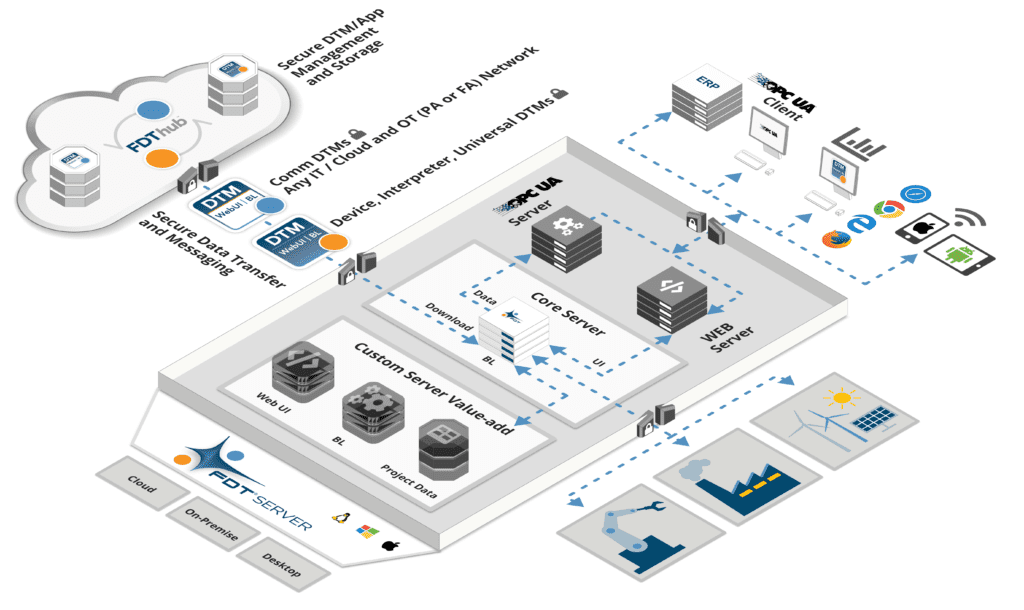

Automation product developers have reason to be interested in the latest FDT technology developments. The upcoming release of the FDT IIoT Server™ (FITS™) architecture will dramatically change the outlook for the worldwide supplier community. The modernized approach inherent in FITS “lowers the bar” for vendors seeking to take advantage of this innovative technology while greatly optimizing developer performance.

The FITS-enabled FDT Server platform enhances the device supplier business model by allowing creation of a new generation of DTMs that will seamlessly integrate with any Server (multi-user) or Desktop (single-user) hosting environment. This approach holds the key to unlocking universal device integration with important advantages such as platform independence, mobility solutions, and a contemporary development environment to reduce costs and expedite the DTM certification process.

For device vendors, FITS-enabled FDT/DTMs will provide fit-for-purpose solutions for tasks such as deep inspection diagnostics and prognostics enhancements driven by artificial intelligence. All FITS DTMs comply with the NAMUR NE-107 recommendation, which stipulates that operators need a view of the process including the status of the instrumentation in a simple and uniform way—regardless of source device—to support predictive maintenance strategies. The DTMs will also be a key enabler for Apps intended for viewing the health of field devices, and subsequently improve maintenance workflows.

Addressing Supplier Challenges

Despite the importance of FDT/DTMs to the new era of industrial automation, experience has shown that managing these crucial software drivers can be a complex and laborious process. Many suppliers struggle with the challenges of managing DTMs for their customers’ intelligent devices, so having an easy-to-access repository that can store and manage DTMs and Apps would be extremely beneficial.

Historically, automation end-users have had difficulty finding the FDT/DTMs they need to deploy field devices within their automation project. A project involving a hundred unique field devices, for example, could require up to 15 minutes to locate each device DTM—and thus involves several days’ worth of installation work. This engineering burden had the potential to put device commissioning on the critical path.

FDT Group’s FITS platform development addresses traditional device configuration challenges by incorporating a cloud-based FDThub™, which provides a centralized location for hosting of all FITS-capable DTMs (based on the FDT 3.0 specification). Future plans call for expansion of the repository.

The FDThub provides convenient access to certified FITS Device and Communication DTMs in a single, online repository. This versatile resource is designed for cloud-based or air-gapped Desktop/Server deployment with automatic asset discovery, as well as support for machine-to-machine communications with 509 electronic security certificates for machines with authorized access. An end-user with a FITS-enabled Server or Desktop application at one of their locations simply applies for access to the FDThub for that site. Upon approval by FDT Group, they receive a 509 certificate that can be installed within their respective application. This step provides automatic authorization for the application to access the repository in the background to obtain DTMs. No password or log-in information is required.

When implementing an automation project, end-users won’t have to go searching for FDT/DTMs for their field devices. All of the correct DTMs will be located in the FDThub and made available for automatic download and installation. As such, there will no longer be a need for control engineers or maintenance technicians to visit individual device manufacturers’ websites to obtain the appropriate device software.

Any time the FITS application determines that a device has been added to a network, it will retrieve the proper FDT/DTM without requiring operator intervention. If a device is already installed, FITS will check the FDThub to determine if a new DTM is available, and if so, it will give the end-user the option to utilize the new DTM or continue operating with the existing software.

For use with the FITS solution, all DTMs must be certified. Once a DTM is sent to an independent test lab for certification and passes the required tests, it is immediately forwarded to FDT Group for uploading to the FDThub. This approach streamlines the certification process and eliminates the need for manual intervention by device suppliers. They can provide their customers with immediate access to current DTMs without having to maintain a hosting website, distribute CDs, etc. The entire DTM distribution process is transparent to the end-user; as soon as they install the vendor’s device, the DTM automatically appears for it. The FDThub also assists the supplier community by providing automatic export compliance.

Benefits for Automation Stakeholders

The FDThub offers significant benefits for both automation manufacturers and end-users around the world. Its cloud-based repository capability eliminates a number of DTM management headaches for device vendors while providing end-users with greater confidence and ease of use.

With the FDThub, certified FITS-based FDT/DTMs can be automatically downloaded from the cloud for use in on-/off-premise server and desktop applications. The repository provides convenient DTM/App storage and device management, as well as secure data transfer and messaging with proactive user alerts when DTM updates are available.

The FDThub also makes it possible to deploy “FDT as a Service” with convenient online access to the latest certified FDT/DTMs. A helpful device discovery capability triggers automatic download or search results in the case of multiple DTMs. The repository provides a secure portal allowing vendors to authorize/de-authorize customers; view reports and download history; upload, update, remove, or suspend DTMs; and configure their export compliance.

Conclusion

With the FDThub, instrumentation end-users will no longer have to search for the device software need need—locating FITS DTMs only takes a matter minutes since all certified DTMs are available at a single, online location. This is another example of the modern, user-friendly features provided by the FITS platform for the industrial automation sector. FDT Group has listened to the marketplace and responded to its needs with key technology advancements.

Image Downloads

FDT IIoT Server Platform