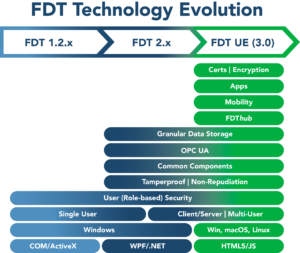

FDT Group™, an independent, international, not-for-profit industry association supporting the evolution of FDT® technology, today introduces the FDT Unified Environment (UE), and developer tools based on the new FDT 3.0 standard to deliver next-generation FDT industrial device management system and device solutions for field-to-cloud IT/OT data harmonization, analytics, services, and mobility based on user-driven requirements for smart manufacturing in the process, hybrid, and discrete markets.

Driven by digital transformation use cases to support new Industrial Internet of Things (IIoT) business models, the standard has evolved to include a new distributed, multi-user, FDT Server application that includes built-in and pre-wired OPC UA and Web servers enabling an FDT Unified Environment (FDT 3.x) merging IT/OT data analytics supporting service-oriented architectures. The new Server environment deployable in the cloud or on-premise delivers the same use cases and functionally as the previous generation FDT hosting environment, but now provides data storage for the whole device lifecycle at the core of the architecture allowing information modeling and data consistency to authenticated OPC UA and browser-based clients (tablets and phones) for modern accessibility to address the challenges of IIoT.

“Collaboration and data harmonization are the keys to manufacturing modernization,” said Steve Biegacki, managing director, FDT Group. “FDT UE delivers a data collaborative engineering specification and toolset to enable modern distributed control improving operations and production reliability impacting the bottom line for new IIoT architectures. I’m proud to witness our first group of members showcasing their FDT 3.0 WebUI-based DTM prototypes mixed with 2.0 DTMs in the new Server and Desktop environments running IO-Link and HART here at Hannover Messe live and in person. To be present as a guest in the OPC Foundation booth to demonstrate field-to-cloud connectivity, OPC UA enterprise access and services along with mobile field device operation is one for industry history books. I especially want to thank Thomas Hadlich, FDT architecture and specification chairman, for leading the first FDT UE demo project; along with our front runner member companies for participating – Flowserve, Krohne, Omron, Magnetrol, Thorsis, CodeWrights, VEGA, Rockwell Automation, Turck, PACTware and M&M Software.”

“Collaboration and data harmonization are the keys to manufacturing modernization,” said Steve Biegacki, managing director, FDT Group. “FDT UE delivers a data collaborative engineering specification and toolset to enable modern distributed control improving operations and production reliability impacting the bottom line for new IIoT architectures. I’m proud to witness our first group of members showcasing their FDT 3.0 WebUI-based DTM prototypes mixed with 2.0 DTMs in the new Server and Desktop environments running IO-Link and HART here at Hannover Messe live and in person. To be present as a guest in the OPC Foundation booth to demonstrate field-to-cloud connectivity, OPC UA enterprise access and services along with mobile field device operation is one for industry history books. I especially want to thank Thomas Hadlich, FDT architecture and specification chairman, for leading the first FDT UE demo project; along with our front runner member companies for participating – Flowserve, Krohne, Omron, Magnetrol, Thorsis, CodeWrights, VEGA, Rockwell Automation, Turck, PACTware and M&M Software.”

FDT UE consists of FDT Server, FDT Desktop, and FDT DTM components. System and device suppliers can take a well-established standard they are familiar with and easily create and customize standards-based, data-centric, cross-platform FDT 3.0 solutions—expanding their portfolio offerings to meet requirements for next-generation industrial control applications. Each solution auto-enables OPC UA integration and allows the development team to focus on value-added features that differentiate their products, including WebUI and App support. FDT Desktop applications are fully backward compatible supporting the existing install base.

FDT 3.0 specification license agreements and developer toolkits are now available on the FDT website (www.fdtgroup.org/resources).

About FDT Group AISBL

The FDT Group AISBL is an international non-profit corporation consisting of leading worldwide member companies active in industrial automation and manufacturing. The major purpose of the FDT Group is to provide an open standard for enterprise-wide network and asset integration, innovating the way automation architectures connect and communicate sensor to cloud for the process, hybrid and factory automation markets. The FDT standard is globally adopted by IEC 62453, ISA 103, and GB-T 29618-2017 with millions of Device Type Managers (DTMs) in use. FDT Technology benefits both manufacturers and end users, with advancements such as the Industrial Internet of Things (IIoT) and Industrie 4.0 delivered out-of-the-box – enabling modernized asset integration and access to performance data for visualizing crucial operational problems. Around the world, end users, manufacturers, universities, and research organizations are working together to develop the technology; provide development tools, support, and training; coordinate field trials and demonstrations; and enable product interoperability.

###