Industrial Internet of Things (IIoT) applications promise huge business opportunities. Suppliers of automation systems and devices are seeking to speed up product development efforts to seize the potential of this emerging market.

However, control and instrumentation vendors face unique development challenges compared to other markets. Companies designing next-generation IIoT devices must produce enhanced functionality within limited time and budgets. Leveraging modernized, user-friendly developer toolkits can increase overall efficiency.

FDT Group is driving continued developments in open, standardized, universal network/device integration and asset management. The FDT ecosystem is evolving to incorporate modern web-based and mobile applications in the process, hybrid and discrete manufacturing markets.

The release of updated Common Components toolkits supporting the new FDT 3.0 standard promises to simplify the development of FDT-based IIoT solutions. Utilization of these advanced toolkits can alleviate many development challenges by helping to improve engineering efficiency while increasing productivity, quality and security.

Advancing the FDT standard

For suppliers of industrial control products and solutions, implementation of FDT Group’s standard is a forward-looking strategy supporting the new era of automation. Thanks to ongoing advancements, FDT technology now offers greater flexibility for developers with innovative solutions supporting IIoT and Industrie 4.0, including applications opening the door for standardized sensor-to-cloud and enterprise-wide integration.

FDT Group’s IIoT transformation path to connect and empower the intelligent enterprise has been based on industry-driven feedback. The organization’s standards developments have focused on security, performance, ease of use, and investment protection to allow automation suppliers and end-users to take advantage of an evolving open integration and information sharing architecture. These features, embedded in suppliers’ system and device offerings, are elevating their product line to meet the digital transformation pathway demanded by the industrial sector.

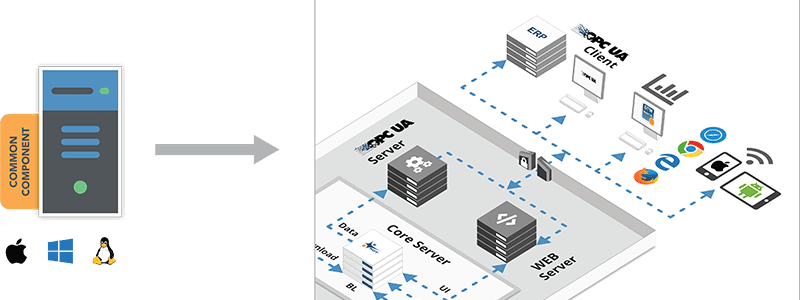

The recently released FDT 3.0 standard supporting the FDT IIoT Server (FITS™) platform will enable vendors to enhance their product offerings with standards-based, platform-independent, information-driven business models for the process, hybrid and discrete manufacturing markets. FITS will empower the intelligent enterprise by transforming manufacturing practices, enabling open, secure and scalable skid-to-cloud deployment architectures and sensor-to-cloud integration with embedded OPC Unified Architecture (UA) and Web Servers, as well as built-in security features and deployment options for cloud, enterprise, edge, on-premise, and single-user desktop environments.

Indeed, FDT 3.0 will accelerate the transformation journey into the Fourth Industrial Revolution by enabling an ecosystem of FDT-based solutions to meet demands for IIoT and Industrie 4.0 applications. This updated, platform-independent standard delivers a comprehensive, cloud-based asset management solution deploying a secure-by-design environment, IT/OT integration, universal compatibility benefits and a single FDThub repository for FDT Device Type Managers™ (FDT/DTMs™).

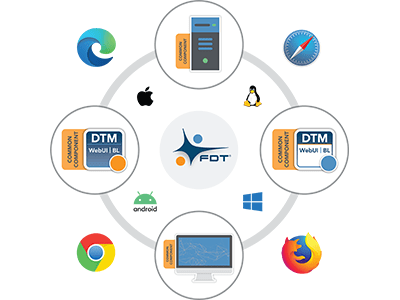

With FDT 3.0, FDT DTMs have evolved with business logic moving to Microsoft .NET Core technology to provide device data and the user interface moving to web-based technology to present asset-related information. This approach eliminates the constraints imposed by a traditional Windows environment.

Additionally, since FITS-based DTMs automatically make device data and health information available via the OPC UA server embedded on the FDT Server, asset management is now deployable as a cloud service as part of an IIoT initiative. The FITS architecture flattens the automation pyramid so that any application requiring data from devices can retrieve it directly from OPC UA through the DTM.

Improving developer performance

Automation product developers are welcoming FDT Group’s latest technology advancements. Release of the FITS architecture will dramatically change the outlook for the worldwide supplier community. The modernized approach inherent in FITS will benefit vendors seeking to take advantage of this innovative technology while greatly improving developer performance.

Over the years, automation solution providers have streamlined their techniques for development of FDT-based products. Whereas developers once spent a tremendous amount of time writing code just to enable features required by the standard, they can now utilize FDT Group’s Common Components to create a library of routines that simplify the development process and save countless hours of R&D time, while also allowing engineers to focus on value-added functionally to achieve a competitive advantage. These toolkits have proven to be popular with leading controls and instrumentation manufacturers that have developed and deployed FDT-enabled stand-alone applications, host systems and FDT DTMs.

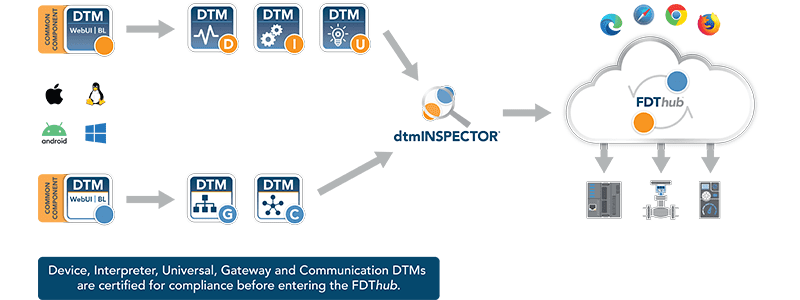

With the introduction of the FDT 3.0 standard, FDT Group has released associated Common Components toolkits to help the vendor community jump start FDT development with a modernized Integrated Development Environment (IDE) to create next-generation, data-centric FITS solutions, including compliant FDT Server, FDT Desktop and FDT DTM components. The updated Common Components—the only platform-independent testing tools of their kind in the industry—help to minimize engineering effort, simplify FDT DTM certification and shorten time to market for new product offerings.

Leading developer organizations supporting FDT Group have devoted thousands of engineering hours to the Server, DTM and Desktop Common Components with the goal of optimizing R&D efforts within the automation vendor community. The toolkits have all been tested together to ensure a high level of confidence in the interoperability of different generations of supplier components. Furthermore, working groups within the FDT organization developed Server and DTM prototypes in tandem to ensure they work and interact in a seamless manner.

FDT Group maintains a change control board comprised of representatives of leading automation companies for each of its Common Components. Board members play an active part in the progress of the technology and are responsible for approving and managing the project schedules for any changes required within the tool sets.

Leveraging industry expertise

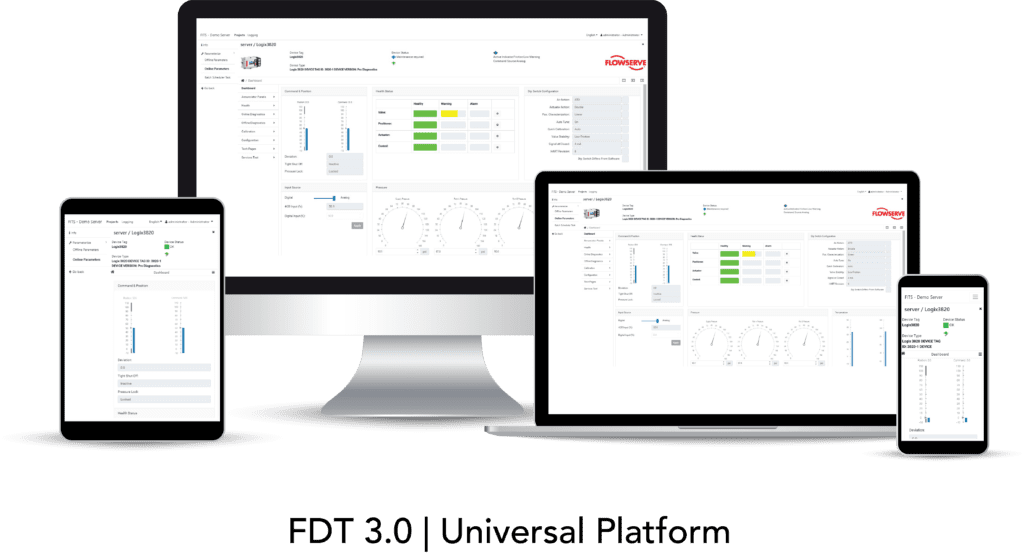

Manfred Gundel, head of business unit device integration, M&M Software, indicated that FDT 3.0-based Server Common Components can take advantage of a new web user interface to enable a true client-server concept. “The robust webUI with this toolkit allows DTMs to be opened in any browser, including mobile devices carried by field personnel. The native integration of OPC UA also makes it possible to publish data for a wide-range of purposes. This will benefit end users as an out-of-the-box solution for accessing DTM information and making it available to cloud-based applications. The Common Components will also be helpful for developers who want to extend their system capabilities with FDT technology.”

Gundel added, “In older FDT versions, the user interface for DTMs was bound to the Windows platform. This prevented FDT-based applications from being fully distributed. The use of web technology now makes it possible to create a true distributed architecture and separate the user interface from the server. The client, server and DTMs are all thin and can be hosted on any platform.”

The FDT 3.0 Server Common Components incorporate a Core Server to manage DTMs, as well as OPC UA and Web Servers. Users have the flexibility to implement any or all the server components, or even integrate their own OPC server if needed. The FDT Server can scale from a large distributed control system (DCS) application all the way down to a machine builder who simply wants to monitor the health of their skid package. There is also the option to use the Common Components to offer FDT as a service.

FDT Server Common Components Empowers Innovation

Gundel noted that the FDT Desktop Common Components have been in existence since the original FDT 1.0 standard and have been upgraded to support all existing versions of the technology. This toolkit does not have a web user interface, but rather is implemented in stand-alone applications without the use of an OPC UA server. It is primarily intended to enhance existing systems with FDT functionality.

According to Robert Hartman, senior developer, CodeWrights GmbH, the FDT DTM Common Components are a valuable asset for automation suppliers bringing new or enhanced FDT DTMs to the market. “FDT DTM Common Components provide a fast way for development teams to view DTMs in an FDT Desktop application and understand the communication flow between them. The toolkit’s web UI allows them to see how different DTMs work together across various machines and operating systems. This is a significant improvement over the previous .NET environment,” Hartman said. “The FDT DTM 3.0 Common Components allow developers to easily create manifest files, package their DTMs and focus on the code they need for their hardware. In addition, the test kit improves interoperability and eliminates misinterpretations of the standard when updating DTMs from FDT 2.0 to the FDT 3.0 standard. It also includes a new deployment package that works on all platforms.”

Hartman continued, “With the recent FDT technology enhancements, DTMs now natively offer data through OPC UA. This feature eliminates a significant amount of effort on the part of developers; they can implement FDT 3.0 using the Common Components and then rely on the toolkit’s clear guidance to support interfaces within the standard.”

FDT DTM Development Process

Increasing engineering efficiency

With the release of its platform-independent 3.0 standard, FDT Group has taken additional steps to ensure that its complete, integrated tool chain can be employed on any platform. This approach allows automation suppliers to immediately develop FDT-compliant products for their platform of choice.

The FDT Server and DTM Common Components, utilizing pure Microsoft .NET Core technology, create an environment allowing for quick and easy development so system and device vendors can focus on custom/value-added features that will differentiate their products from competitors. These toolkits, available for use with any of the major operating systems, ensure specification compliance, greatly enhance interoperability, and work together to help developers deliver an ecosystem of FDT IIoT-enabled solutions while expediting time to market.

For example, the standard FDT Server Common Components toolkit has a built-in, platform-independent OPC UA Server that is prewired, pretested and ready for immediate deployment. This solution alleviates headaches for developers by eliminating the learning curve for implementing an OPC UA Server and integrating it with an FDT application. The toolkit integrates a pre-built Web Server to support all the browser-based clients in the FITS architecture, and it can even be compiled and employed as a working FDT Server out-of-the-box, without the need for any additional engineering.

For device vendors, the FDT 3.0 standard makes it easier to create compliant device DTMs than ever before. Thanks to the DTM Common Components, DTMs are automatically compatible with OPC UA and compliant with the NAMUR NE 107 status recommendations for predictive maintenance. FITS-based DTMs automatically make device data and health information available via the OPC UA server embedded on the FDT Server. This empowers innovative business models such as a data-driven approach to maintenance, rich integration of live plant data with manufacturing execution systems (MES), enterprise resource planning (ERP) systems and asset management as service.

Thanks to the FDT 3.0 standard and Common Components toolkits, automation suppliers can take advantage of a completely integrated development environment employing Microsoft Visual Studio. This makes it possible to produce an FDT Server or DTM that works on any of the major operating systems (macOS, Linux, Microsoft), which will empower the intelligent enterprise by bridging the current FDT installed-base with next-generation solutions supporting IIoT and Industrie 4.0.

Thanks to the FDT 3.0 standard and Common Components toolkits, automation suppliers can take advantage of a completely integrated development environment employing Microsoft Visual Studio. This makes it possible to produce an FDT Server or DTM that works on any of the major operating systems (macOS, Linux, Microsoft), which will empower the intelligent enterprise by bridging the current FDT installed-base with next-generation solutions supporting IIoT and Industrie 4.0.

A unique advantage of FDT 3.0 is the ability to create a web-style Graphical User Interface (GUI) in HTML5 and JavaScript—eliminating common coding challenges and freeing automation developers from the legacy Windows environment. Moreover, implementation of the FITS solution within FDT 3.0 provides the only open platform, standardized integration architecture with a single interface enabling mobile access cloud-to-plant-floor.

Take a look at Flowserve’s FDT 3.0 Server Solution Prototype

The FDT 3.0 Common Components were specifically designed with rigorous security requirements in the mind. FDT Group’s security working group analyzed specific threats to the FITS client-server architecture and made its findings available for review by member companies. All ingress and egress points from the client and server are protected by industry-standard, multi-layered security measures such as Transport Layer Security (TLS) enabling Web Sockets Secure (WSS) and Hyper Text Transfer Protocol Secure (HTTPS) capabilities. This security strategy encompasses encrypted communications using TLS, role-based user security, X.509v3 certificates for device authentication, and on-the-wire-security for enabled industrial control protocols.

Conclusion

The new FDT 3.0 standard supporting the FITS platform will simplify the move to IIoT and Industrie 4.0, providing native OPC UA integration, Web Services, mobility, and control to enhance connectivity and information sharing across control system platforms. These and other opportunities will transform the outlook for industrial automation stakeholders around the world.

The automation supplier community can use FDT 3.0 Common Components to simplify development of FDT Server, FDT Desktop and FDT/DTM components. These tools greatly enhance interoperability across a product portfolio while improving engineering efficiency, reducing the time for certification and accelerating products to market.