While many emerging technologies are crucial to advancing the Industrial IoT (IIoT) – including advanced analytics, artificial intelligence (AI) and machine learning (ML) – according to ARC Advisory Group research, connected smart assets and especially the digital twin are having the most immediate and significant impact on how companies implement smart manufacturing.

Digital Twins In A Converged World

A digital twin is a virtual copy of something as straight forward as a device or as complex as an entire business system. Created using data from sensor technologies, the data gives users both structural and operational views of what happens to the device or system in real-time. With that data, users can monitor, model, and adjust the digital twin to see how virtual changes would affect the original device or system before committing to the change in the real world.

As more companies move toward the IIoT and converging Information Technology (IT) and Operational Technology (OT), digital twin is one emerging technology that can impact the entire industrial architecture – product solution ecosystem, communication, and integration standards.

IT is focused on the use of computers, storage, networking, infrastructure, and processes to create, process, store, secure and exchange all forms of electronic data. OT includes hardware and software that detects or causes a change through the direct monitoring and/or control of intelligent sensors and actuators.

While IT and OT have different interests and requirements, the merging of these worlds opens the door to innovative IIoT solutions – like digital twins. This technology is revolutionizing a manufacturer’s ability to use integrated IT/OT data to design and employ models that form the basis for increasing overall efficiency, quality, and agility.

Visualizing Your Factory

Converging IT/OT data in one platform supports visualization of the factory as a whole. This is how OT and IT decision-makers will receive productivity status updates consistently and on time, which enables them to make more accurate business decisions.

Manufacturers looking for IT/OT convergence benefit from a secure, scalable, and adaptable platform that provides embedded configurable end-to-end trusted interoperability supporting cloud, edge, on-premises, or enterprise-wide agile architectures.

FDT’s strength in visualization and data analytics enables seamless integration of automation system assets (current installed-based and new solutions), control applications and edge devices throughout the global industrial sector, as well as expanded access to critical operational data. This strength extends to emerging technologies – like digital twin – supporting:

- Better decision making

- Improved data insight and visualization

- More modern and consistent workforce training

- Efficient standard operating procedures

FDT (3.0) Unified Environment Enables Multi-Purpose Digital Twins

Because a digital twin represents a real-world object, like a device, it can be used for planning, simulation, commissioning or enabling access to the object. Often a digital twin serves one purpose, but many projects use one digital twin for multiple purposes, like planning and simulation.

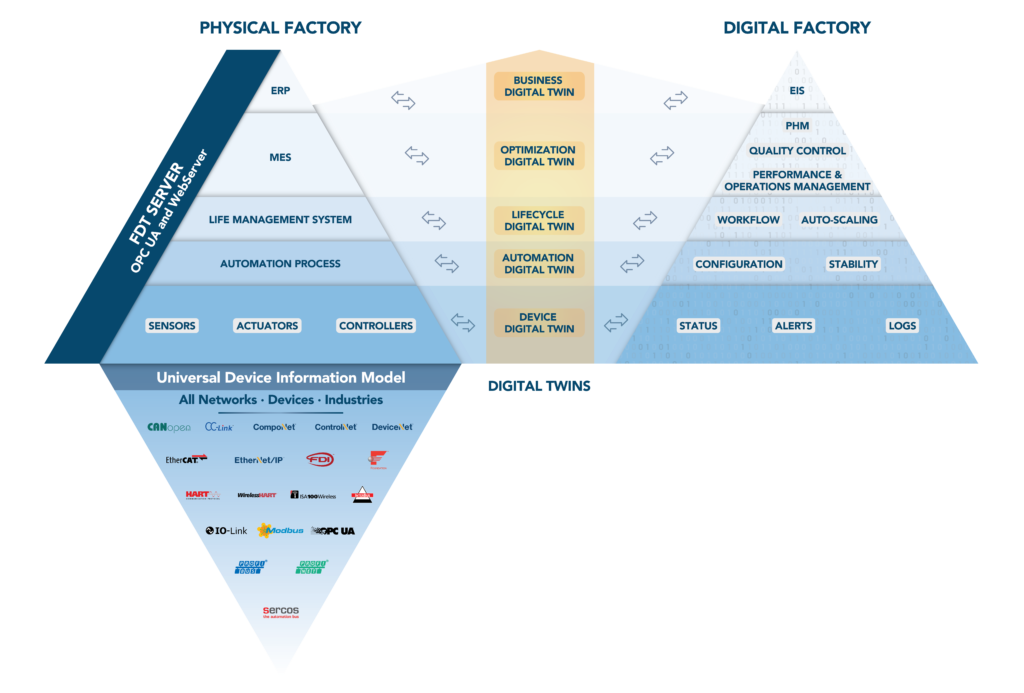

FDT brings together the worlds of IT and OT, and systems and devices. Because the FDT server environment encompasses two servers, there are operating benefits and economic (business) benefits for different configurations and simulations of devices or processes. Digital twin drives data analytics and operational insight. The strength of FDT has always been analytics – and now those analytics are even richer, with better device diagnostics and better performance.

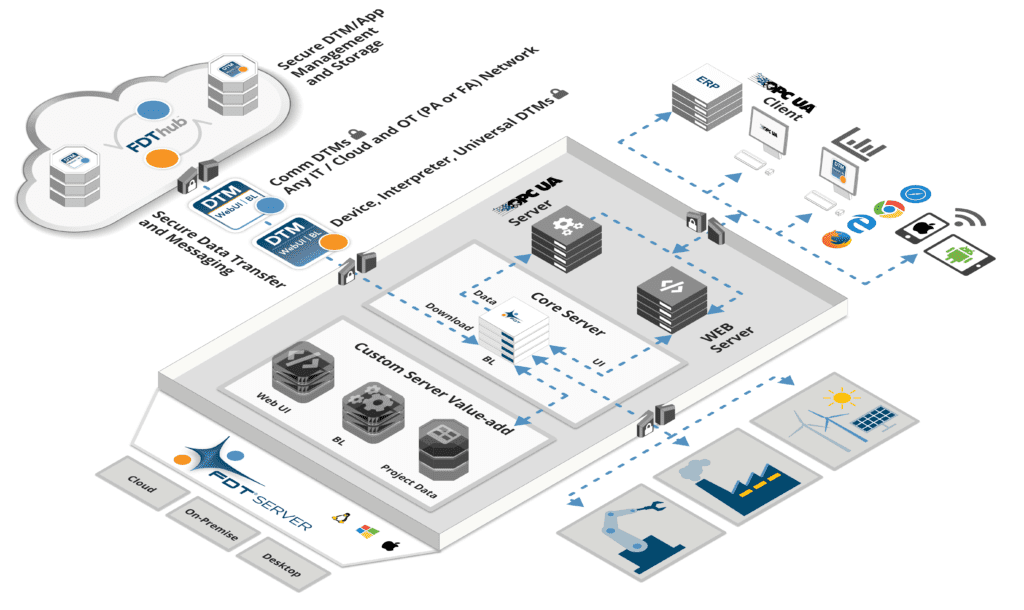

For industrial companies seeking proven solutions supporting the convergence of business information and plant operating technologies, FDT Group’s new FDT Unified Environment, (also known as the FDT3 standard), with its FDT Server and built-in OPC UA Server solution, enables robust IT/OT integration and provides a secure gateway to network/device data and health information. The standard offers OPC UA Client/Server-authenticated access to plant application data, and its utilization of a Publish-Subscribe environment allows for real-time data exchange.

FDT Device Type Manager™ (DTMs) provide documents for device types as well as for specific device instances to extend support to other use cases. For instance, it is possible to provide an eCL@ss description for a device type to support detailed engineering or link maintenance documents for a device instance to support lifecycle management. The DTM can serve as a hub to all device-related information.

FDT3 provides an accepted standard for deploying and integrating a digital representation of a device to many platforms. Because of FDT3, it is possible to integrate a DTM into a web server, which allows remote access to device-related services like monitoring, diagnosis, and parameterization. Also, it is possible to integrate DTMs into an OPC Server, that supports application-level integration – for asset management or for ERP, for example. The OPC Server may support an information model according to the FDT OPC Unified Architecture (UA) Information Model.

Major Benefits of Digital Twin Environments

The FDT Server with OPC UA enables system providers with digital twins for simulation and virtualization of automation systems, I/O systems, and processes.

The main reasons for introducing digital twin technology into a production system is to improve access to information related to the production process and to improve the flexibility of the production system. This applies to existing production systems as well as to newly planned production systems.

Figure: Embedded FDT Server environment enables digital twins, sensor to cloud

For FDT, supporting access to device-related information is not new – it’s been a core competency for more than 20 years. Originally, the capability was mainly as an in-process representation of the device, but with FDT unified environment the focus has evolved from an in-application representation of the device to provide a server-based representation of the device. With the FDT environment, it is possible to have one server which provides a package of device-related information and services. The server then can be used to support very different use cases related to the device.

A DTM provides packaged information about all supported device types. Today this typically includes documentation as well as protocol support files. It would be easy to use the DTM to provide files for simulations or for virtual commissioning. If such files are provided via a link, the device vendor could maintain and update such files without updating the DTM.

The business benefit for device vendors is that they need to support only one solution for multiple purposes. The DTM package can support traditional service and IoT use cases. The business benefit for end-users is that they can use a well-established, mature technology as the base for their information access.

Digital Twin Improve Plant Design and Operational Performance

Digital twin improves control and configuration for the lifecycle – including improving plant design and operational performance – through semantic interoperability.

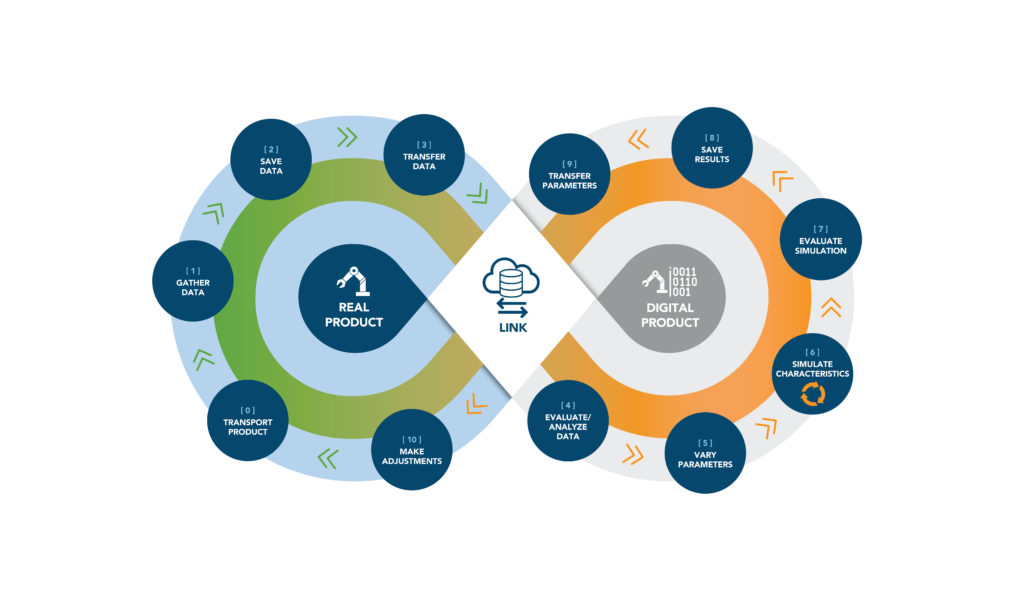

Figure: FDT Server enables digital twin product simulation as part of the lifecycle

Currently, there are many ways of providing support for plant design. Also, there is no common solution for transferring knowledge from the early phases of the production system lifecycle (like from plant design) to the operation phase.

If the device data for supporting plant design would be annotated with semantic information, it would be easier for system planners and operators to understand device data and the relationship between the planning data and the current configuration of the device. With the FDT OPC UA information model, it is possible to access this information from any user application.

Expanded Connectivity in the Modern World

Implementing the FDT/OPC UA model offers expanded connectivity of engineering, distributed control, asset management and other systems as part of IIoT and applications in the modern connected world.

FDT is the only open, scalable, secure, and interoperable architecture for the modern industrial enterprise. The technology provides a vendor-neutral software interface for integrating assets and delivering access to device intelligence for end-users with process, factory (discrete) and hybrid operations. In these diverse markets, with unique operational requirements, the technology enables a common environment for utilizing smart devices’ most sophisticated features.

This architecture allows everyone and everything – people, processes, and technology – to work better together.

Figure: FDT (3.0) unified environment for modern industrial device management and device transport

Commissioning and start-up are two of the most crucial use cases for digital twins, as people become less dependent on physical devices. The value of the digital twin is in quicker configuration and modernization of lifecycle processes in a simulated environment.

Imagine operating with all the accuracy but without the boundaries of a physical device. The simulated device can understand the environment and send values back to the user. The information model is coming directly from the device.

FDT is bridging the real world and the virtual world, enabling secure communication across any network and hierarchy of networks allowing modeling of any protocol or device. With digital twins, it will be possible to change applications and use DTM’s to configure, simulate, check behavior, make decisions and learn from history.

FDT’s expertise in control enables digital twin so both vendors and users will realize significant benefits.