Control system engineers can use FDT today with certainty that there will be seamless integration when FDI is available in the future

A technologist’s adaptation of Abraham Lincoln’s quote about the common man might be “God must love standards because he made so many of them.” While everyone gains significant benefits from industry standards, many design teams might often wish there were fewer of them.

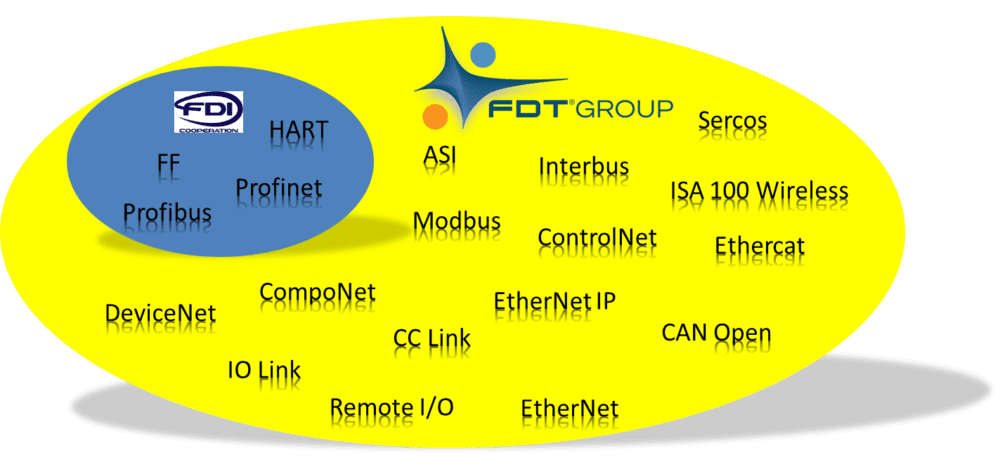

That’s generally true in industrial automation, where a number of different communication networks have risen over the past few decades to handle the many diverse automation and production environments. They all developed with the goal of making it easier to link different types of products together. Each focuses on differing requirements for those in the disparate world of industrial automation – process, factory or hybrid. Some standards brought a common connection technique years ago when most companies had proprietary connections. Others augment existing standards with, for example, real time capabilities.

The good news is that the FDT standard makes it easier for communication network  managers to access devices in the many facilities that use more than one of these field communication networks. FDT Technology simplifies device integration and brings information from intelligent devices using different communication protocols together to provide a single point of access to device information. It provides independence in many categories such as field communication protocol, control system, device supplier or process, factory or hybrid manufacturing environments.

managers to access devices in the many facilities that use more than one of these field communication networks. FDT Technology simplifies device integration and brings information from intelligent devices using different communication protocols together to provide a single point of access to device information. It provides independence in many categories such as field communication protocol, control system, device supplier or process, factory or hybrid manufacturing environments.

Many people may not think they have multiple communication networks or hybrid environments. But in fields like brewing and pharmaceuticals, many different technologies are used throughout a single facility and the enterprise. FDT supports most, if not all, of them. The standard operates with PROFIBUS DP, PROFIBUS PA, HART, FOUNDATION Fieldbus H1/HSE, Interbus, PROFINET, Modbus TCP/RTU/ASCII, Ethernet/IP, EtherCAT, DeviceNet, ControlNet, IO-Link, ASInterface, SERCOS, CC-Link, ISA100 and CANopen.

FDT has been evolving and gaining devotees for the past 10+ years, achieving well documented success. The FDT Group membership exceeds 90 device and system/host suppliers who have included FDT Technology on more than 7,500 devices supported by certified DTMs (Device Tool Managers). As an IEC 62453, ISA103 and China GB-T 29618 standard, it enables interoperability of device information designed to work in facilities that have multiple or hybrid communication networks to improve plant reliability, lower cost and maximize their intelligent assets.

Today, asset management applications are used to configure, monitor and diagnose devices and as well to diagnose fieldbuses and networks since many gateways provide valuable segment and network diagnostics. The application can be a stand-alone PC based tool or embedded in a control system. FDT DTMs provided by device suppliers provide an easy to use, graphical interface to support configuration, diagnostics and troubleshooting of critical measurement devices and other assets.

FDT Technology was designed to be fully compatible with the soon-to-be released FDI (Field Device Integration) standard. Users can be assured that their investment in FDT-enabled tools and devices today can be used in the FDI solutions of tomorrow.

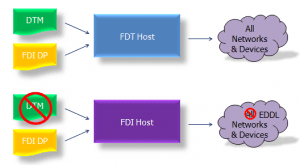

The new FDI standard aims to simplify integration within ‘process’ automation networks that are EDDL-based (Electronic Device Description Language) such as HART, FOUNDATION Fieldbus and PROFIBUS. FDI is designed from the ground up to be compatible with FDT Technology. FDI products are expected to be available in 2016.

The FDI standard defines a collection of device information, called a Device Package (DP). These DPs, consist of a bundling of the DD/EDD, an optional graphical user interface and optional attachments such as certificates, datasheets that are currently available in the FDT DTM.

Integrating FDI into FDT brings the best of both worlds without compromises. Control system and network engineers can support devices on all communication networks using an FDT-enabled host. They can also access all process variables, diagnostics, configuration and other device resources from DD, EDD, DTMs and FDI Device Packages. FDT Technology enables access to process, factory and hybrid automation applications – bringing together information from multiple communication networks.

As seen in this graphic, an FDT-enabled host is the only host that is able to accept and use both FDT DTMs and FDI Device Packages. As shown, an FDI host is able to accept FDI Device Packages that support HART, FF and Profibus. For all automation networks including hybrid automation applications, FDT provides the highest level of device information integration, flexibility, ease of use and standardization. FDT is the low-cost, low-risk technology- enabled solution available today and prepared for the future.

As seen in this graphic, an FDT-enabled host is the only host that is able to accept and use both FDT DTMs and FDI Device Packages. As shown, an FDI host is able to accept FDI Device Packages that support HART, FF and Profibus. For all automation networks including hybrid automation applications, FDT provides the highest level of device information integration, flexibility, ease of use and standardization. FDT is the low-cost, low-risk technology- enabled solution available today and prepared for the future.

There no way around it, both FDT and FDI are important to the process industry. Control system engineers can use FDT today with certainty that there will be seamless integration when FDI is available in the future. Together, these two standards can make life much easier for those who work in facilities that have multiple networking architectures. Hybrid networks become much easier to manage and expand when standards handle the many facets of connecting devices to a diverse group of networks. And with FDT, you get all features and functions from all Device Packages and DTMs and all major field communication networks are supported and fully integrated. So there is no reason to wait! Use the FDT Standard today that is prepared for the future!