The purpose of this whitepaper is to provide information related to the topic of device integration using FDI Device Packages with FDT Group’s publicly available FDT standard.

Background

The FDT (Field Device Technology) standard, IEC 62453, advanced by the FDT Group, and started more than ten years ago, provides a platform for intelligent device integration across all industrial communication networks spanning process and discrete automation. FDT’s nested communication allows transparent information flow from devices to host systems across different industrial communication networks. Sixteen different industrial communication networks, tethered and wireless are fully supported and integrated into the FDT standard.

FDT 2.0 Technology

Over time, the technologies used to implement FDT 1.x became dated. The FDT Group developed a concept to further their standards and enable easier adaptation of future technologies. This resulted in a future-proof architectural concept for a new version of FDT known as FDT2™. FDT2 is based on the .NET Framework and uses the scope of functions available in Windows Presentation Foundation (WPF) and Windows Forms libraries, among others. In addition, FDT2 implements persistent storage of device instance data to speed access time to device data. Interoperability, performance and operation of the DTM and FDT Frame applications are also optimized by the introduction of what are called Common Components.

Backwards Compatibility of FDT 2.0

In recognition of the large installed base of DTMs built on the FDT 1.x specification, the FDT2 specification was designed to ensure backward compatibility. Therefore all available DTMs from the FDT 1.x specification will work in FDT2 Frame-based systems ensuring investment protection throughout the life cycle of a plant.

Openness of FDT Technology

Device Selection

Users can select various manufacturers’ devices and easily integrate the best in class devices into their applications. The selection can be oriented towards the performance features of the device rather than the specifications of a system manufacturer or a communication protocol. The same applies for the FDT Frame Application.

FDT imposes no limitations on an innovative device technology as long as the DTM interface remains compatible. Investments are thus protected long-term. New communication protocols are regularly added to the FDT specification through protocol annexes. Backward compatibility of new interface descriptions is a requirement for all FDT working groups.

Integration of Device Descriptions

For devices which do not have a native DTM, but only a Device Description (DD) or Electronic Device Description (EDD), so named Interpreter DTMs are available. Interpreter DTMs are not uniquely programmed for a device, but rather use existing Device Description files created for a certain device. Usually these DTMs have fewer graphic and functional features because of the limited properties of the Device Description language (EDDL). One example is the “IO-Link Device Description interpreter DTM”, which interprets DDs from IO-Link devices for factory automation and, with its help, can provide parameters for these devices. There are further Interpreter DTMs, through which EDDs for HART, PROFIBUS PA and FOUNDATION Fieldbus devices are interpreted. For upcoming new Device Description formats FDT will be easily expanded by providing a corresponding Interpreter DTM, as it has been done before.

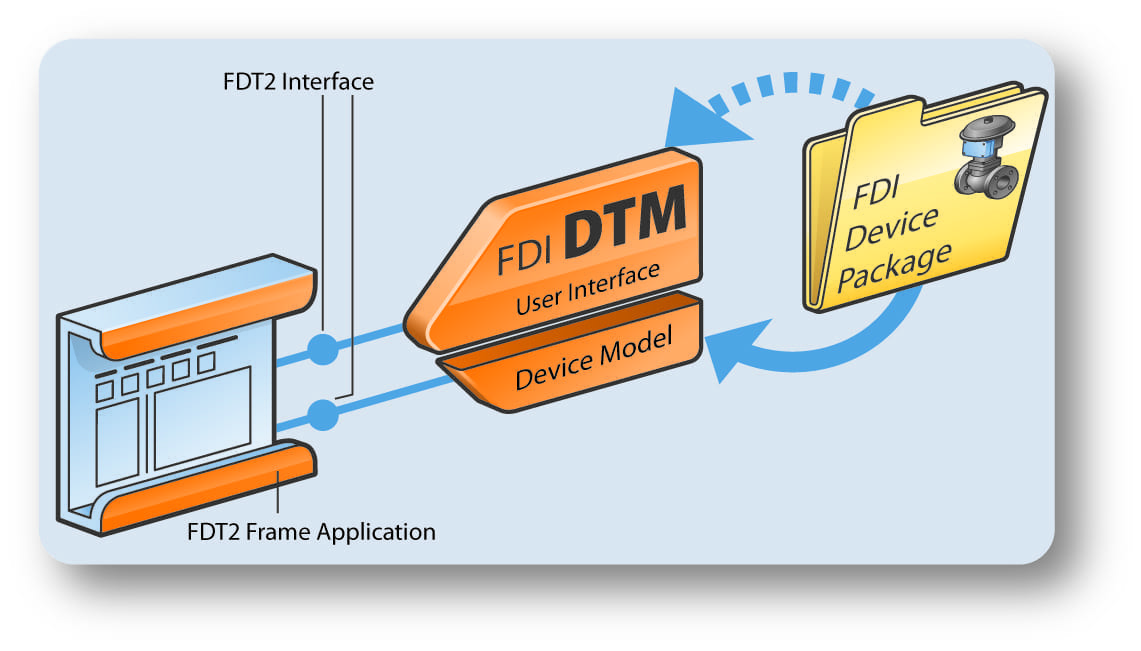

Interoperability of FDT 2.0 with FDI

FDI® (Field Device Integration) is focused on device integration for process automation applications using HART, PROFIBUS, and FOUNDATION Fieldbus based devices. The goal of FDI is to provide a common solution based on device integration technologies: (Electronic Device Description Language) and DTM (Device Type Manager) Technology. The FDI Device Package will address the requirements for simple and complex devices for process applications. FDI Device Packages can be processed in FDI Hosts as well as in an FDT2 Frame Application. This allows device suppliers to create an FDI Device Package for their devices containing both: an EDD and an optional UIP (User Interface Plug-in) that provides additional graphical capabilities similar to a DTM. Host suppliers are free to implement an FDI host, or an FDT2 frame application. End users in the process industries benefit because both solutions will use the same FDI Device Packages to provide the same functionality and experience. The FDT Group and FDI Cooperation are both committed to support this approach and ensure that FDT2 based systems can use and deliver the full functionality of FDI Device Packages. Hosts that are based on the FDT2 frame specification will process FDI Device Packages using an FDI DTM. This FDI DTM will be based on the same tools that are used to develop a native FDI host.

(Electronic Device Description Language) and DTM (Device Type Manager) Technology. The FDI Device Package will address the requirements for simple and complex devices for process applications. FDI Device Packages can be processed in FDI Hosts as well as in an FDT2 Frame Application. This allows device suppliers to create an FDI Device Package for their devices containing both: an EDD and an optional UIP (User Interface Plug-in) that provides additional graphical capabilities similar to a DTM. Host suppliers are free to implement an FDI host, or an FDT2 frame application. End users in the process industries benefit because both solutions will use the same FDI Device Packages to provide the same functionality and experience. The FDT Group and FDI Cooperation are both committed to support this approach and ensure that FDT2 based systems can use and deliver the full functionality of FDI Device Packages. Hosts that are based on the FDT2 frame specification will process FDI Device Packages using an FDI DTM. This FDI DTM will be based on the same tools that are used to develop a native FDI host.

FDT Hosts Provide the Broadest Solution

Supported Networks

A native FDT2 host system supports more than 16 network protocols including the 3 supported by a native FDI host. The FDT2 standard is designed in such a way that additional future networks can be added without re-releasing the standard or modifying an existing FDT2 host system. This feature proofs the interoperability with new networks as they come onto the market. Vendors have also used this feature to deliver seamless support for proprietary or legacy protocols. In addition, an FDT2 based host is optimally suited to implement device and asset management tasks as it integrates seamlessly both FDI Device Packages and device DTM’s.

Tunneling

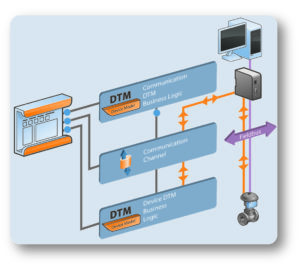

Unique to the FDT architecture is the ability of an FDT2 host system to natively communicate with end devices by tunneling through any number of disparate networks and associated gateways. This so called nested communications occurs without the host needing to intervene in any way and without modifying the communications stack of any of the networks through which the tunneling occurs.

Future Extend-ability

The FDT architecture allows communication adapters and gateways to be added to an FDT2 system without explicit support from the host through the use of communication DTMs. End users therefore can pick best in class network components and extend FDT2 based host systems as new devices and networks become available. Recent trends in communication DTMs have shown significant advancements in network level diagnostics delivering proactive maintenance indicators previously only available with specialized hardware and software. As networks communicate faster and through wireless mediums, the advantage of the integrated network configuration and predictive diagnostics becomes a game changing advantage.

Summary

FDT as a standard for device integration fulfills the requirement to offer to the user a free selection of all components installed in their system, independent of the manufacturer, and with it the option of being able to use the most suitable devices for their applications. Moreover, the open FDT Technology protects investments of the plant operator in field device technology for the long term and makes it possible for device manufacturers to create uniformity in device drivers running in different system environments.